Adsorbents

The importance of ceramics to ceramic fillers-Xintao Technology Molecular Sieve Manufacturer

by:Xintao Technology

2022-04-14

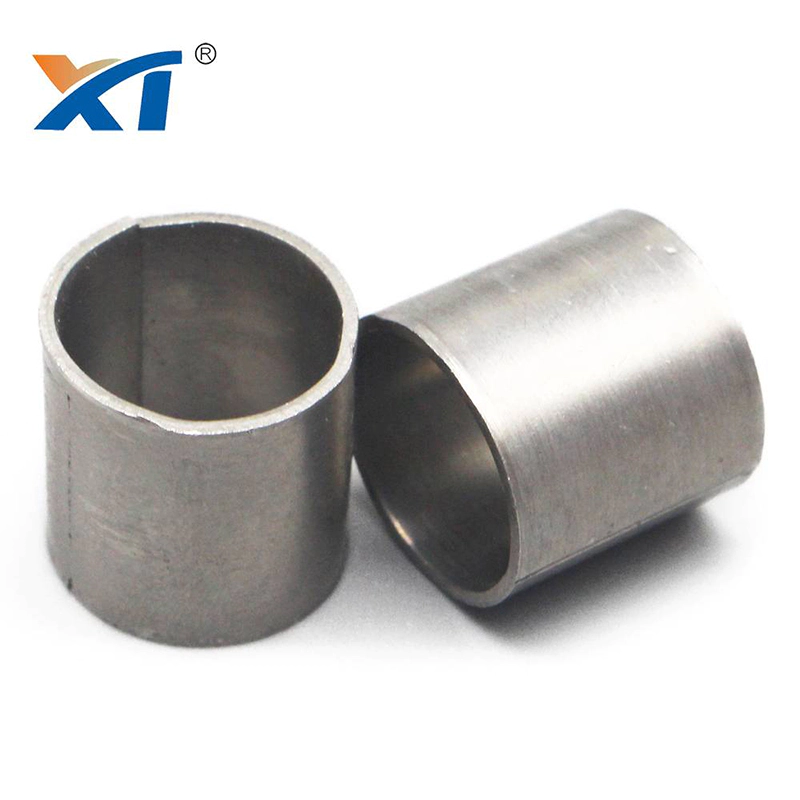

In general, it can be used for the purification of some industrial compounds, absorbs corrosive mixtures, and is used as a heat exchanger by everyone. Ceramic structured packing is more efficient than dispersant packing, with less compression and more flexible operation. Ceramic structured packing has very strict requirements on ceramics. They require not only good chemical resistance, but also impermeability, high mechanical strength, excellent thermal stability and excellent resistance to rapid temperature changes. But at the same time it is difficult to meet these requirements, so according to different requirements, three types of chemical ceramics can be produced, such as acid-resistant ceramics, acid-resistant temperature-resistant ceramics, and industrial ceramics. Regarding the thermal stability and resistance to temperature changes of the ceramic, the thermal conductivity, linear expansion coefficient, elastic modulus and tensile strength of the ceramic should also be considered. When the thermal conductivity coefficient is large, the temperature difference of each part after the ceramic part is heated is small. The linear expansion coefficient is small, and the deformation amount when the temperature changes is small. In addition to hydrofluoric acid and fluosilicic acid, chemical ceramics can withstand almost all concentrations of inorganic acids and salts and organic media. It has poor corrosion resistance to phosphoric acid and cannot resist alkali, especially concentrated lye. Silicates are easily formed due to the large amount of silicon dioxide (SiO 2 ) and lye contained in ceramics. Ceramic structural fillers have excellent heat resistance and corrosion resistance, and can be used in chemical, metallurgical and other industries, including more than 40 kinds of Raschig rings, cross stop rings, etc. Since there are some devices in the ring, the compressive strength is high, the structure is reasonable, and the efficiency is high. Of course, the application of ceramic structural fillers is also necessary. When the elastic modulus is small, the deformation amount of the phase change material has a small deformation stress. When the tensile strength is larger, the allowable thermal deformation stress is larger, so the thermal stability and temperature change resistance of the material are better. Since ceramics are used as fillers, unlike chemical equipment, the allowable operating temperature is much higher than when used as equipment, and the operating temperature can reach 1200-1600°C.

Custom message