Jiangxi Xintao Technology Co., Ltd.

There is chemical industry there is Xintao chemical packing.

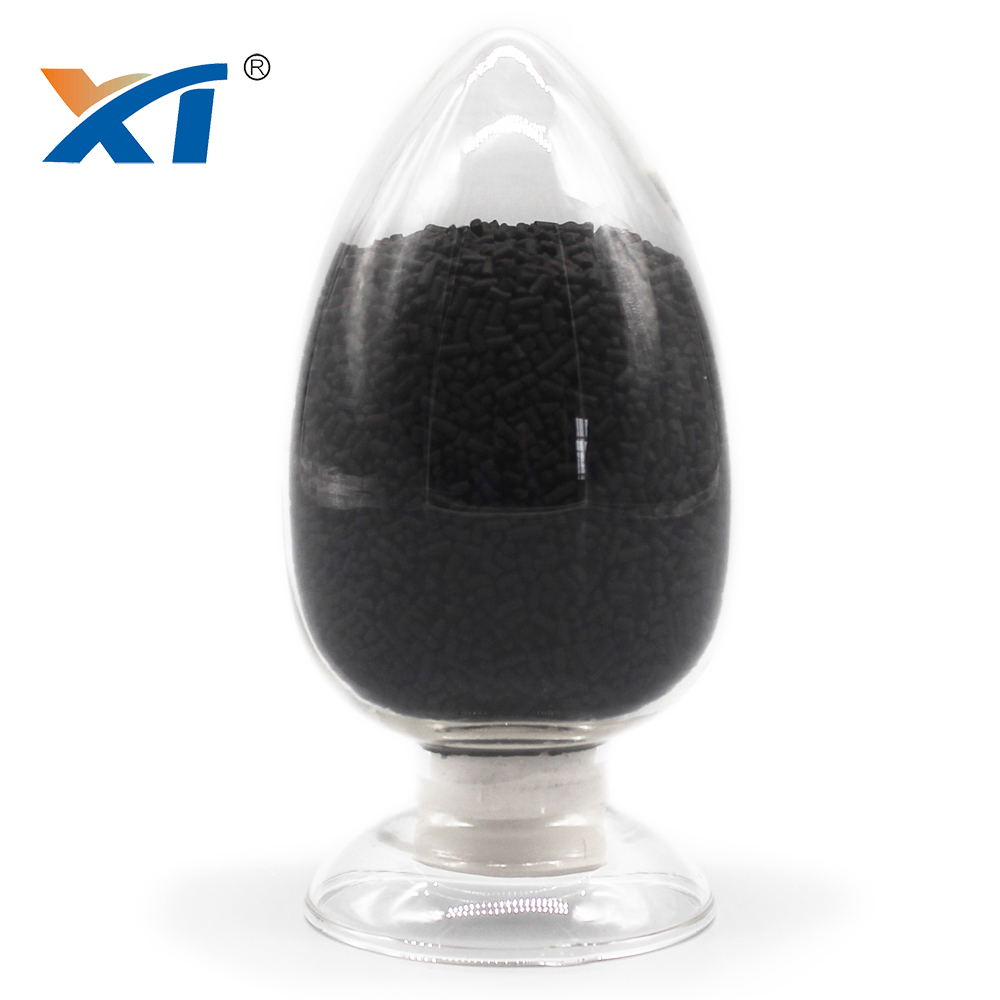

Carbon molecular sieve is a kind of nonpolar carbon adsorptive material which has nanometer level ultrafine micropores. It is composed of micropores, some mesoporous and large pores.

Carbon molecular sieve is used in preparation of hydrogen and nitrogen in chemical industry, sewage treatment in environmental protection, military gas mask in military protection and some other areas because of its pore structure and stable chemical properties. For example,carbon molecular sieve is used in concentrating methane of coal bed gas by pressure swing adsorption, which has the globally economic and environmental meaning of energy saving and emission reduction.

Adsorption properties of carbon molecular sieve largely depend on its microstructure. So it is significant to characterize the microscopic structure of carbon molecular sieve. Since the 1970s, the technology of preparing the carbon molecular sieve has great progress. Raw materials and preparation methods have a great impact on the performance of carbon molecular sieve.

In recent years, as carbon molecular sieve has a very high value in utilizating coal mine gas, the requirements of antistatic and explosion-proof of carbon molecular sieve are also improved.

Oxygen Application and Uses

Electric Steelmaking: Decarburization, Oxygen Heating, Foaming Deep Slag, Metallurgical Control and Subsequent Heating

Wastewater treatment: oxygen-enriched aeration of activated sludge, pool oxygenation and ozone sterilization

Glass melting: Oxygen-assisted combustion and dissolution, cutting, increasing glass output, extending furnace life

Pulp bleaching and papermaking: conversion of chlorine bleaching to oxygen-enriched bleaching, provision of cheap oxygen, sewage treatment

Non-ferrous metal smelting: Oxygen enrichment is required for smelting uranium, zinc, nickel, lead, etc. The PSA method is gradually replacing the cryogenic method

Field cutting construction: Oxygen-enriched for field steel pipe cutting, mobile or small oxygen generators can meet the requirements

Oxygen for petrochemical and chemical industry: Oxygen reaction in petroleum and chemical industry uses oxygen-rich instead of air for oxidation reaction, which can improve the reaction speed and chemical product output

Ore processing: used in gold and other production processes to improve the extraction rate of metals

Aquaculture: Oxygen-enriched aeration can increase the dissolved oxygen in the water and greatly increase the yield of fish; it can supply oxygen for the transportation of live fish: intensive fish farming

Fermentation: oxygen-enriched instead of air; supplying oxygen for aerobic fermentation can greatly improve efficiency

Drinking water: ozone sterilization

Working Principle

The oxygen production equipment is carefully developed according to the "PSA" pressure swing adsorption principle, using high-quality oxygen-producing zeolite molecular sieve as the adsorbent, and directly separates and produces oxygen from the air at room temperature. After; the compressed air pretreated by drying and drying, under the action of pressure swing adsorption, realizes the separation of oxygen and nitrogen. The adsorption characteristics are selected by the molecular sieve, nitrogen is adsorbed in the zeolite molecular sieve, and oxygen is enriched in the gas phase, which is output as a product. The system is equipped with two adsorption towers, one tower absorbs oxygen, and the other tower desorbs and regenerates, cycle alternately, and continuously produce oxygen.

Features

In 1970, PSA technology made a breakthrough in industrial application, and it was first used in air drying and purification.

PSA oxygen generator technology is a high-tech energy-saving separation technology that directly produces oxygen from the air at room temperature. It has been applied for decades.

This series of devices has the advantages of compact equipment, small footprint, fully automatic operation, reliable operation, fast start and stop, small production and maintenance at room temperature, etc. The oxygen purity and oxygen production can be properly adjusted, and there is no environmental pollution. on-site oxygen generator.

Main Specifications

Oxygen flow: 3~200Nm3/h

Oxygen purity: 90~95% (standard should be 90%)

Oxygen pressure: 0.2MPa (can be increased to the pressure required by the user)

Dew point: -60~-40℃

Where to Buy Carbon Molecular Sieve?

Jiangxi XINTAO Technology Co., ltd in China is an ISO certificated 20 years manufacturer specialized in molecular sieve.

We provide a variety of high standard products. Xintao Carbon Molecular Sieve is highly appreciable in nitrogen generation.

Our products range: Molecular sieves(3A, 4A, 5A, 13X, 13X APG, 13X-HP, IG, Lithium MS);Carbon molecular sieve; Activated molecular sieve powder;

Requst For Quotation

WhatsApp: +86 13576431529

E-mail: export@xt988.com

Copyright © Jiangxi Xintao Technology Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a responsefrom us via email. Please be sure to leave yourcontact details so that we can better assist