Carbon molecular sieve (CMS) , takes the appearance of cylindrical black solid, contains countless 4 angstrom fine pores. The main component is element carbon. It is a new and one of the few non-polar adsorbent that specializes in separating oxygen from nitrogen under the normal temperature and pressure, also it is an important part in natural gas processing.

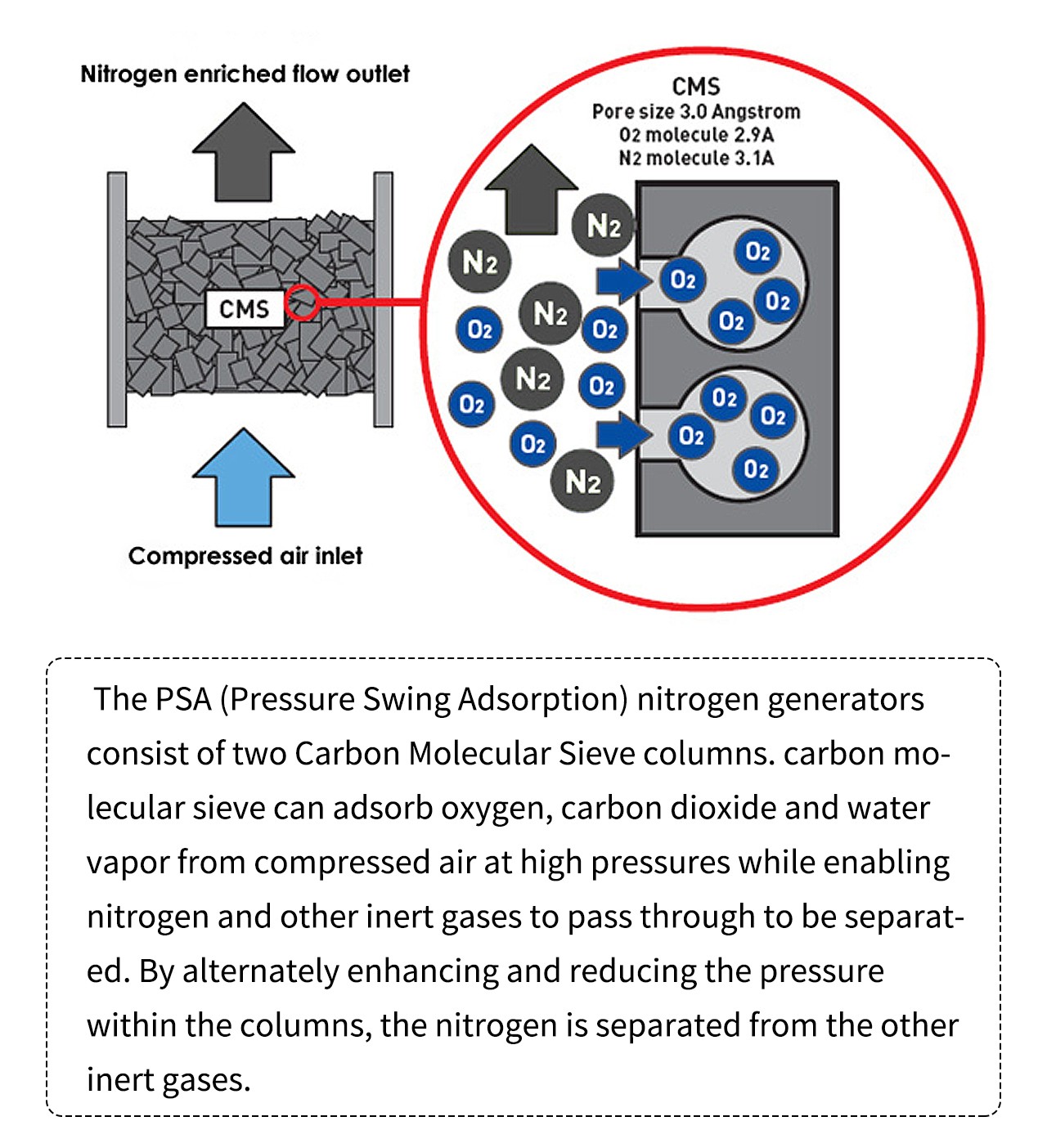

How does carbon molecular sieve work?

CMS adsorbs oxygen gas, carbon dioxide gas, moisture and so on in compressed air in a short period of time and compressed nitrogen gas is available at the outlet. When the pressure decreases to the atmospheric or vacuum level, CMS which has adsorbed oxygen gas and others easily desorbs them and is regenerated.

What types of carbon molecular sieve do we have?

Xintao provide CMS220, CMS240,CMS260 and CMS280

There are different diameters to choose from 1.1-1.3mm, 1.3-1.5mm to 1.5-1.8mm etc.

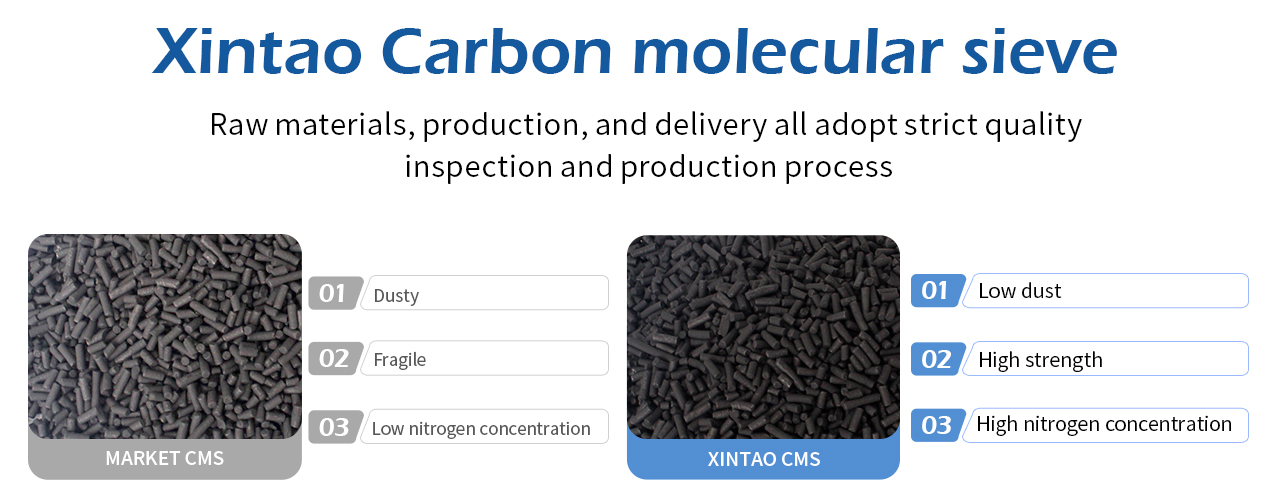

Xintao Carbon Molecular Sieve, has the character of large N2 yield capacity and high N2 recovery. It has long service life, is suitable for various types of PSA nitrogen making machine.

Copyright © Jiangxi Xintao Technology Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a responsefrom us via email. Please be sure to leave yourcontact details so that we can better assist