Jiangxi Xintao Technology Co., Ltd.

There is chemical industry there is Xintao chemical packing.

1. Oxygen generator equipment type: VPSA

2. Installation location/time: China. 2022.07.03

3. Tower diameter (inside): 2.68m Height: 6.5m

4. Loading capacity: (1) A total of 14 tons of 5A oxygen production Molecular sieve, 7 tons/tower (2) 2.5 tons of activated alumina, 1 ton/tower

5. The main technical performance requirements of the customer: Oxygen flow rate 350Nm³/Hr Oxygen concentration ≥ 93%±2%

After installing Xintao oxygen molecular sieve, the flow rate is 340 -380Nm³/Hr Oxygen concentration 95.6%

6. Requirements for the purchase of screens and cotton cloth:

(1) Requirements for 304 stainless steel wire mesh: Tower diameter (mm) X4 (4 pieces in total, 2 towers, 2 pieces for each tower, one piece for the upper layer and one piece for the bottom layer)

(2) Requirements for non-woven cotton: Tower diameter (mm) X4 (total 4 pieces, 2 towers, 2 pieces for each tower, one piece for the upper layer and one piece for the bottom layer)

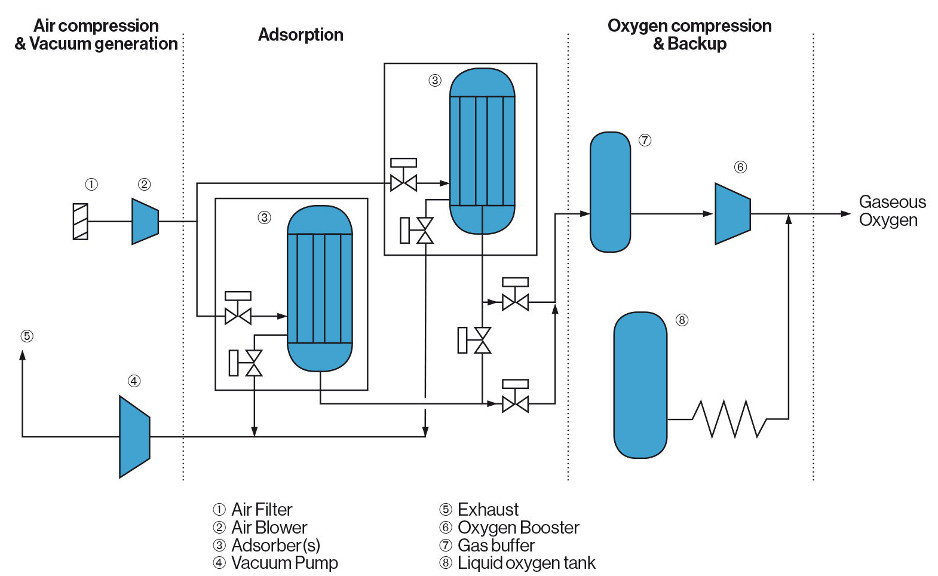

VPSA Oxygen Generator Process

VPSA oxygen generator system is mainly composed of blower, vacuum pump, switching valve, adsorber and oxygen balance tank (oxygen compressor, gas storage tank).

The air enters the blower through the filter, and is conveyed by the blower from the adsorption tower department enters. The lower part of the adsorption tower is filled with activated alumina. The function of activated alumina is to remove moisture, carbon dioxide and a small amount of other gases in the air, so as not to "poison" the 5A molecular sieve. The upper part of the adsorption tower is a 5A molecular sieve. When the air flows through the filled molecular sieve fixed bed,the oxygen molecular sieve in the air diffuses into the molecular sieve solid under the adsorption force, and the oxygen molecules pass through the bed to the buffer tank. The buffer tank is connected with the oxygen compressor to compress the product to the pressure required by the user and send it to the gas storage tank for production use.

After a period of adsorption, the molecular sieve particles are filled with nitrogen molecules and reach the adsorption saturation stage. At this time, close the air inlet valve, use the oxygen-enriched air in the tower to flush the other tower that has just been vacuumed, and close the pressure equalization after the pressure drops. At the same time, open the inlet valve of the vacuum pump to evacuate the tower body. After reaching a certain degree of vacuum, use part of the oxygen in the buffer tank of the oxygen-enriched machine in another tower to flush the molecular sieve, so that the adsorbent can be completely desorbed.

Each adsorber of VPSA performs the following steps alternately: Adsorption -------- Vacuum desorption ----- Stamping

(2) The difference between PSA and VPSA

The pressure of PSA oxygen generator is generally 0.5-0.8MPa, and the adsorption pressure of VPSA is 0.05MPA, which is less than 1/10 of that of PSA oxygen generator. The most important thing is that VPSA has lower energy consumption, is more environmentally friendly and green.

austic soda

Copyright © Jiangxi Xintao Technology Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a responsefrom us via email. Please be sure to leave yourcontact details so that we can better assist