Table of Contents

ToggleMolecular Sieves are Used to Dry Syngas in New Energy Industry

In the new energy field, syngas is a key link between traditional resources and clean energy, and its deep purification is a prerequisite for efficient conversion. Moisture removal is particularly crucial, and zeolite molecular sieves are the core technology for achieving this goal.

Composition and Effects of Syngas

Syngas, mainly composed of hydrogen (H₂) and carbon monoxide (CO), is a mixed gas produced through the gasification and reforming of coal, biomass, natural gas, or waste. It plays a key role in the new energy industry chain, such as producing clean fuels, high-value chemicals, and obtaining pure hydrogen. However, syngas inevitably contains water vapor. If not deeply removed, it can lead to poisoning and deactivation of downstream precious metal catalysts, low-temperature ice blockage and corrosion of equipment, seriously threatening production safety and efficiency.

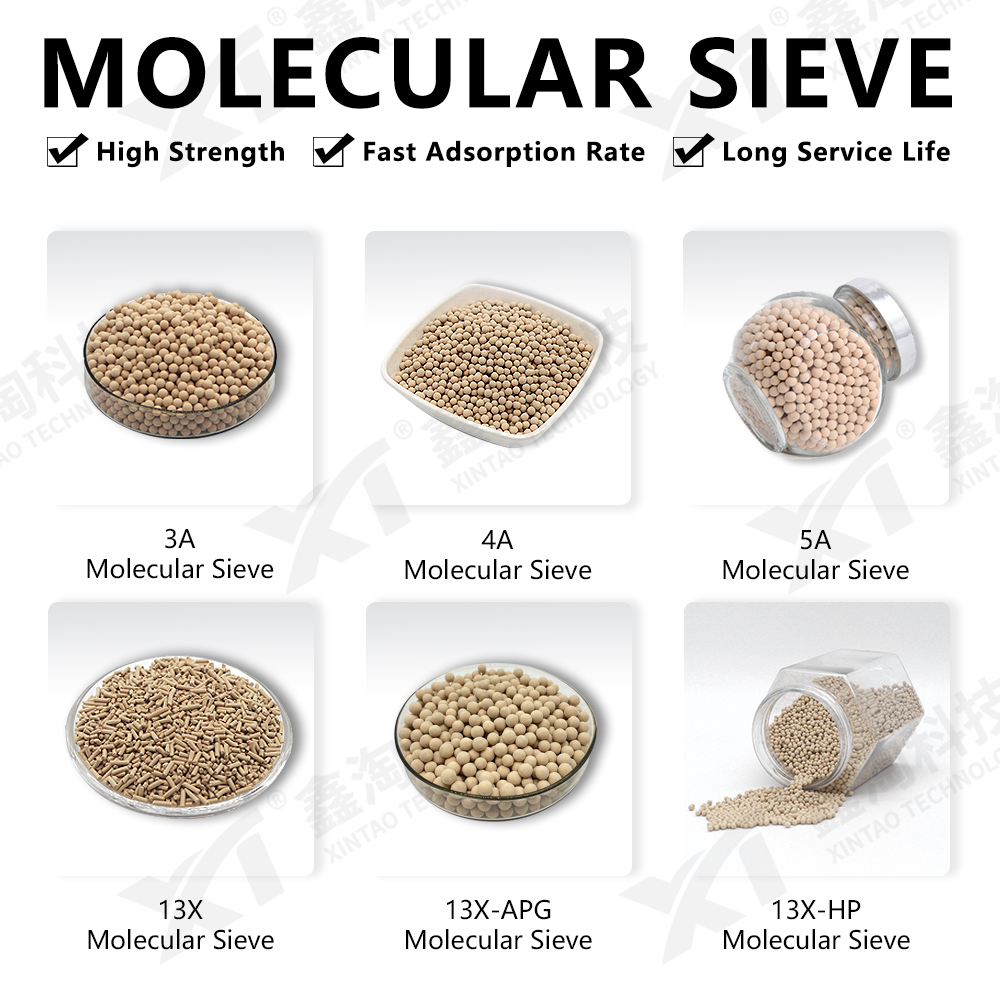

Molecular Sieves

Molecular sieve is artificially synthesized crystalline aluminosilicates with a uniform nanoscale microporous structure, allowing only molecules smaller than the pore size to enter and be adsorbed. It possesses selective adsorption and sieving properties, featuring high strength, large adsorption capacity, fast adsorption rate, good thermal stability, long service life, and regenerability for repeated use. Common forms are spherical and strip-shaped particles, with types including 3A, 4A, 5A, and 13X molecular sieves.

Its working principle is that during the drying of syngas, water molecules (approximately 2.6 Å in diameter) are selectively captured and locked within the pores, while the main components of the syngas (such as H₂ and CO) pass through smoothly, thus achieving deep dehydration.

Why Choose Molecular Sieve for Drying Syngas?

Compared to traditional cryogenic dehydration or solvent absorption methods, zeolite molecular sieve adsorption technology has become the preferred solution for deep drying of syngas due to its unique advantages.

First, Xintao molecular sieves have extremely strong affinity and adsorption capacity for water molecules, reducing the water content in syngas to extremely low levels. They can adapt to a wide range of operating conditions from atmospheric pressure to high pressure and from room temperature to relatively high temperature, exhibiting strong anti-interference capabilities, stable system operation, and long service life.

Second, its adsorption-regeneration cycle is highly automated. After adsorption saturation, regeneration can be achieved through moderate heating (typically 150-350℃) and purging with dry gas, resulting in relatively low energy consumption and continuous operation.

Finally, the deep dehydration of zeolite molecular sieves fundamentally eliminates the risks of catalyst poisoning, equipment corrosion, and pipeline ice blockage caused by moisture, ensuring the long-term, stable operation of downstream synthesis units with substantial investments. It is an indispensable “protective link” in the new energy industry chain.

How to Choose the Right Molecular Sieve?

The composition of syngas is complex, and selecting the appropriate molecular sieve desiccant model is crucial for achieving efficient drying.

- 3A Molecular Sieve: Suitable for scenarios requiring extremely selective dehydration, such as protecting downstream processes that are highly sensitive to CO and H₂ adsorption.

- 4A Molecular Sieve: Suitable for the pretreatment of syngas with relatively simple compositions that require simultaneous removal of water and small amounts of CO₂.

- 5A Molecular Sieve: Can be used to remove specific light hydrocarbon impurities from syngas, or in combination with other models.

- 13X Molecular Sieve: Suitable for the deep purification of complex syngas containing larger molecular impurities or requiring the co-removal of water, CO₂, and sulfides.

In the pursuit of high efficiency and cleanliness in new energy technologies, Xintao molecular sieves, with their irreplaceable deep drying capabilities, efficient recycling processes, and outstanding reliability, provide crucial technological support for the stable passage of syngas, this “energy bridge.” In the future, Xintao molecular sieve adsorbents will undoubtedly provide more efficient, energy-saving, and intelligent solutions for gas purification in syngas and even the entire new energy industry, continuously empowering the transformation and upgrading of clean energy.

Contact Xintao

If you have any question, please contact us!