Table of Contents

ToggleMolecular Sieve - Natural Gas Drying and Purification

Natural gas, as a clean and efficient chemical and petroleum energy source, owes its widespread application to effective purification technologies. Molecular sieve zeolite, with its unique properties, have become an indispensable core material for the deep drying and purification of natural gas.

Composition and Applications of Natural Gas

The main component of natural gas is methane (CH₄), but it also contains small amounts of heavier hydrocarbons such as ethane and propane, as well as non-hydrocarbon gases such as nitrogen and carbon dioxide. During the extraction process, it inevitably contains impurities such as water vapor, hydrogen sulfide (H₂S), mercaptans, and trace amounts of mercury.

If water is present in natural gas, it can form hydrates, blocking pipelines, thereby reducing transportation efficiency and affecting the accuracy of calorific value calculations and trade metering. It can even cause corrosion to pipelines and equipment, leading to leaks and even safety accidents. The content of hydrogen sulfide, carbon dioxide, and hydrocarbons in natural gas varies. If the hydrogen sulfide content exceeds the specifications for marketable natural gas, the excess hydrogen sulfide must be separated from the sour natural gas.

Purified “pipeline gas” or “commercial gas” is an important raw material and energy source for city gas, power plant fuel, industrial furnaces, and chemical production. Its quality directly affects the safety and efficiency of downstream systems.

Molecular Sieve Solutions

To address these issues, Xintao Molecular Sieve provides a reasonable solution. The core principle of molecular sieve adsorbents for natural gas drying and purification lies in their precise physical adsorption and sieving action. Molecular sieves have uniform pore sizes and extremely high specific surface areas. Water molecules can freely enter the pores, while the main component of natural gas, methane, and larger hydrocarbon molecules are effectively blocked. Water molecules entering the pores are firmly adsorbed and captured by the strong local polarity on the molecular sieve framework, thus achieving deep dehydration. After adsorption saturation, the captured water molecules in the pores can be desorbed by heating or depressurization, restoring the drying capacity of the molecular sieve desiccant for continuous production.

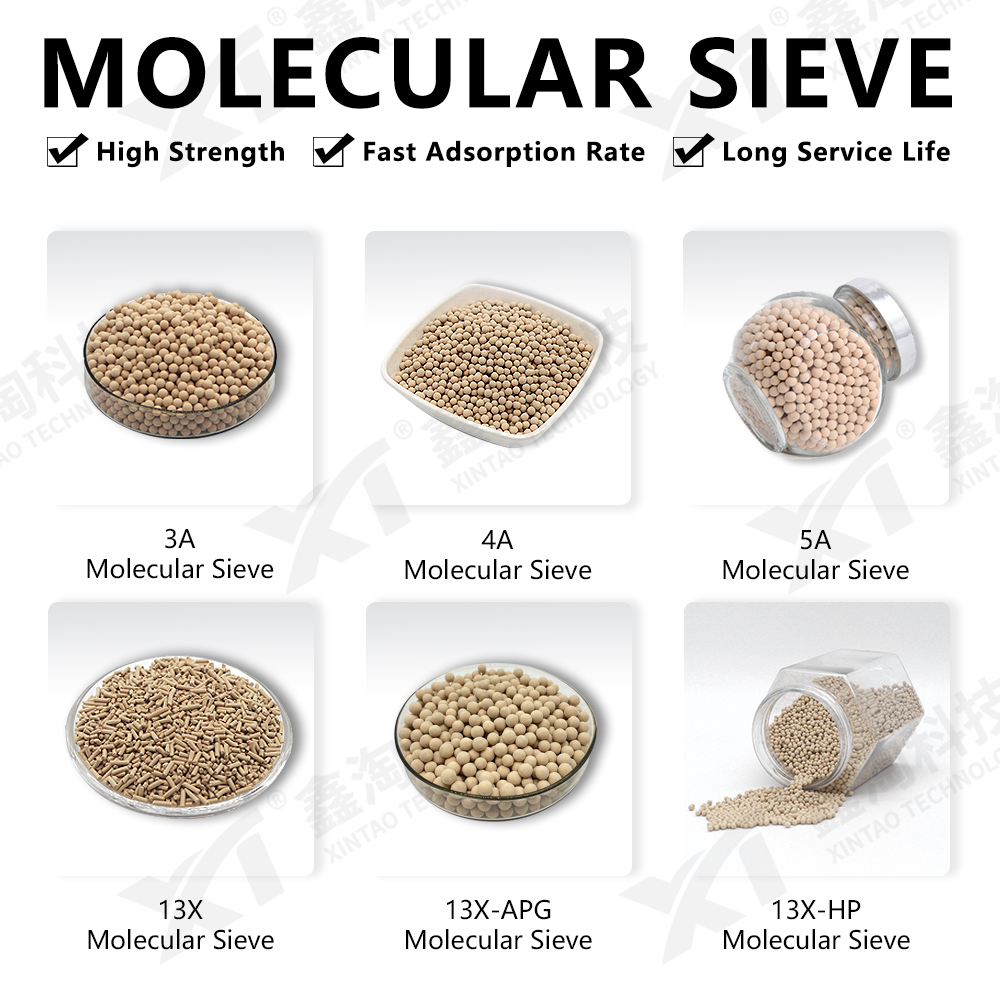

Selection and Advantages of Molecular Sieves

Xintao 3A, 4A, and 13X molecular sieves are commonly used for the drying and purification of natural gas. The 3A zeolite molecular sieve has the smallest pore size and can only adsorb water, making it suitable for applications requiring high protection of hydrocarbons. Molecular Sieve 4A zeolite can adsorb water and some small molecules, but it may lead to co-adsorption problems with heavy hydrocarbons. 13X molecular sieve has the largest pore size and can handle a variety of impurities, making it suitable for applications requiring simultaneous dehydration and removal of acidic gases. For example, if natural gas contains CO2 or H2S, 13X zeolite would be more suitable.

- High quality and high strength

- Fast adsorption speed

- Strong adsorption capacity

- Stable chemical properties

- Long service life

- More regeneration cycles

Molecular sieve, with its excellent selective adsorption capacity, deep drying effect, and stable and reliable performance, has become a cornerstone technology for ensuring the safe long-distance transportation of natural gas and meeting the quality requirements of high-end downstream applications. It eliminates multiple potential problems caused by moisture at the source and are an important part of achieving efficient, green, and safe production in the natural gas industry.

Contact Xintao

If you have any question, please contact us!