Table of Contents

ToggleHow to Deal with Bubbles in Porous Plate Polyurethane Glue?

Aluminum Honeycomb Panel Polyurethane Glue

Two-component polyurethane glue is a solvent-free two-component polyurethane adhesive.

The AB components are mixed and solidified in proportion.

They are prepolymers containing a large number of isocyanate groups and polyether polyester polyols.

The reaction is mainly the reaction between isocyanate group and hydroxyl group to produce urethane.

RNCO+Rˊ—OH→RNHCOORˊ

Water Removal and Defoaming

In order to obtain polyurethane adhesives with excellent performance, the moisture in the raw materials must be strictly controlled during the synthesis process.

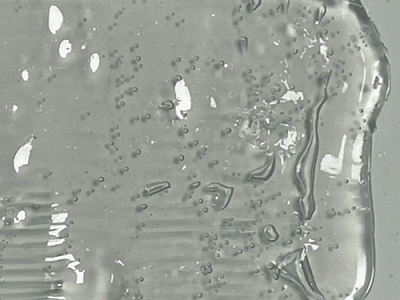

For removing trace amounts of moisture in solvents, molecular sieve materials have great advantages. If the polyurethane AB component raw materials contain trace amounts of moisture, isocyanate will undergo hydrolysis and polycondensation reaction when it comes into contact with moisture. It not only affects the polyurethane synthesis reaction, but also produces a large number of dense small bubbles in the material.

NCO + H2O → R-NH2 + CO2↑

2R-NCO + H2O → R-NH-CO-NH-R + CO2↑

Bubble Problems

- These bubbles formed by gas accumulation inside the material will destroy the continuity of the adhesive and weaken the structural performance.

- Bubbles will increase the porosity and internal defects of the adhesive, and reduce the mechanical strength and density of the adhesive.

- Bubbles will roughen the surface of the adhesive and affect the appearance quality.

- Bubbles reduce the contact area between the adhesive and the substrate and weaken the adhesive force of the adhesive.

- When bubbles exist, it is difficult to discharge them when the adhesive solidifies and shrinks, leaving holes and reducing performance.

- Bubble collapse may also produce stress concentration areas, induce micro-cracks, and reduce the crack resistance of the adhesive.

The trace amount of water in the material may come from the material itself, or it may be absorbed from the humid air.

Therefore, the key to improving the quality of polyurethane glue is to eliminate the trace moisture contained in the raw materials.

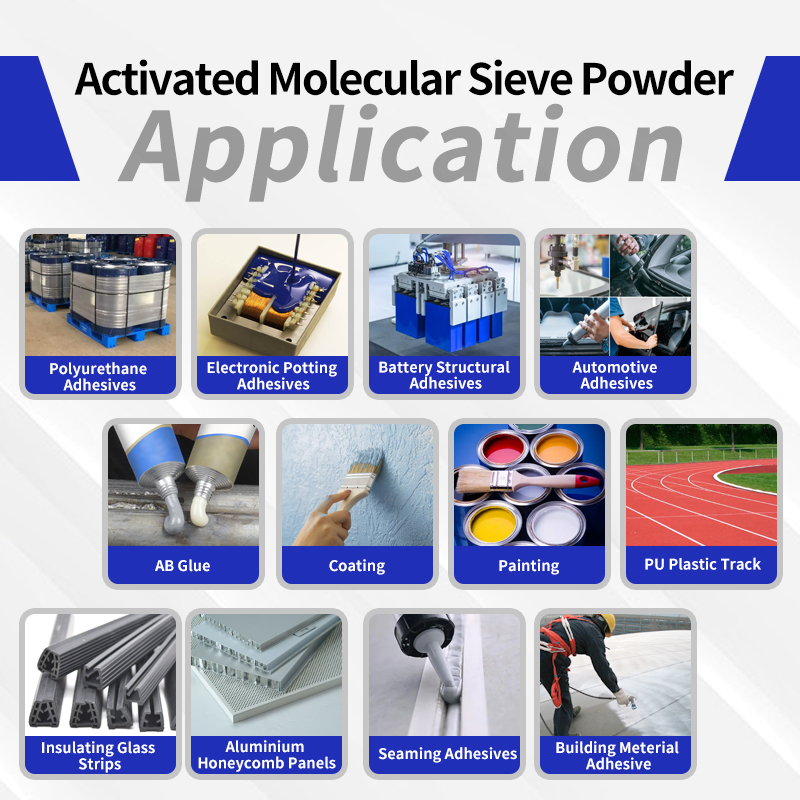

Applications of Activated Molecular Sieve Powder

XINTAO molecular sieve powder is a material with extremely high water absorption accuracy and strong water absorption. By adding less molecular sieves to the raw materials, the polyurethane raw materials can be completely dehydrated and dried. This is the main reason why other dry materials cannot be substituted.

Powder molecular sieve has strong water absorption, and only a small amount of addition can greatly improve the quality of polyurethane. The molecular sieve zeolite powder produced by Xintao has strong diffusibility and no precipitation, and is extremely pure and free of impurities. It has been used in the field of polyurethane synthesis for more than 10 years, and the quality is very stable.

Two-component polyurethane adhesive for honeycomb panels is added with Xintao molecular sieve. It can achieve smoothness without bubbles, no clogging of the gun, no bulges, resistance to climate change, high strength, and most importantly, low cost.

Contact Xintao

If you have any question, please contact us!