Table of Contents

ToggleCombining Molecular Sieve and Activated Alumina

In the industrial gas treatment and petrochemical industries, the synergistic use of molecular sieves and activated alumina has become a core technology for improving drying efficiency and extending equipment life. These two adsorbents, with their complementary physical and chemical properties, form a multi-layered purification system, particularly suitable for industrial applications with stringent moisture and contaminant control standards.

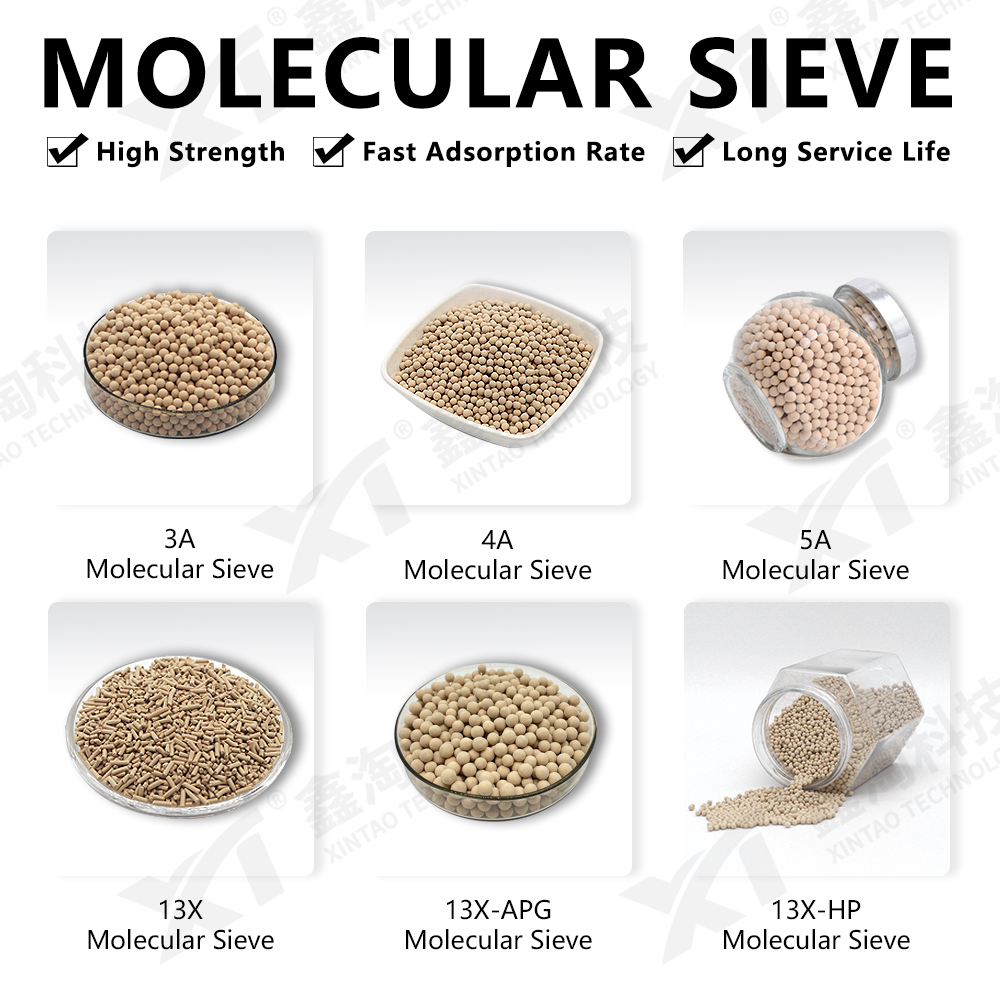

Molecular Sieve

Molecular sieves are microporous aluminosilicate crystals with uniform pore size and extremely high specific surface area. They offer high adsorption capacity, rapid adsorption, and strong adsorption strength. They selectively adsorb molecules smaller than the molecular sieve pore size and exhibit strong selective adsorption for polar substances such as water and carbon dioxide. Zeolite molecular sieves are categorized by their application into 3A, 4A, 5A, 13X, 13X APG, 13X HP, lithium molecular sieve, and carbon molecular sieve.

Activated Alumina

Activated alumina is a porous and highly dispersed adsorption material characterized by high strength, low wear, and resistance to softening, cracking, and powdering in water. Its surface is rich in hydroxyl groups, resulting in excellent adsorption for polar molecules such as water. This allows for high adsorption capacity and low regeneration costs. However, its wide pore size distribution and weak screening selectivity make it suitable for use as a crude adsorption material in the early stages.

Principle of Use

The combination of molecular sieves and activated alumina follows the synergistic principle of “pretreatment and deep, precise treatment,” leveraging the complementary advantages of their performance.

Pre-adsorption Pretreatment: Activated alumina, with its large adsorption capacity, preferentially removes large amounts of water, some heavy hydrocarbons, and other easily adsorbed impurities from the system, reducing the load on the subsequent molecular sieve and preventing frequent regeneration due to rapid saturation.

Deep Screening and Purification: After pretreatment, the material enters the molecular sieve unit, where its uniform pore size and strong selectivity precisely remove residual traces of water, carbon dioxide, or specific molecules, achieving deep purification.

Application Scenarios

Oxygen Generation Industry

In PSA (pressure swing adsorption) oxygen production systems, compressed air first passes through an activated alumina bed, rapidly removing over 80% of moisture and some oil contaminants, preventing moisture from entering the molecular sieve bed and causing it to fail. The pretreated air then enters the oxygen production molecular sieve bed (13X HP zeolite and lithium zeolite), where the molecular sieve selectively adsorbs impurities such as nitrogen and carbon dioxide, ultimately producing oxygen with a purity exceeding 90%. This combination extends the life of the molecular sieve and improves the stability of the oxygen production system.

Natural Gas Purification:

Natural gas extraction often contains significant amounts of moisture, hydrogen sulfide, and heavy hydrocarbon impurities. Activated alumina first acts as a pre-adsorbent, efficiently removing the majority of the moisture and heavy hydrocarbons. The natural gas then enters the molecular sieve bed, further removing any remaining traces of water and hydrogen sulfide. This prevents subsequent pipeline damage from hydrate blockage or corrosion, ensuring safe natural gas transportation.

Contact Xintao

If you have any question, please contact us!