Table of Contents

ToggleThe Structural Characteristics Of The Packed Tower

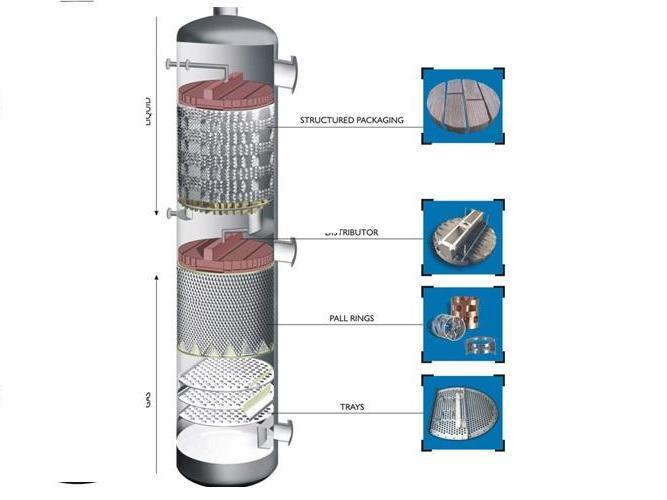

Packed tower is a kind of mass transfer equipment which used the packing in the tower as the contract components between gas and liquid. The body of packed tower is a vertical cylinder, and the bottom is equipped with a packing support plate. The packing is placed on the support plate in a disorderly in integral way.

Tower Packing

PSA is a technology used to separate some gas species from a mixture of gases. The working principle of a PSA nitrogen generator is that under high pressures, nitrogen gas exhibits a strong affinity for adsorbent media such as zeolite or granular activated carbon. Moreover, various gases can be absorbed from a mixture at different rates, depending on the amount of pressure applied.

A packing pressing plate is installed above the packing to prevent it from being blown bu the rising air flow. Liquid is sprayed on the packing from the top of the tower through the liquid distributor and flows down the packing surface. The gas is sent from the bottom of the tower and distributed by the gas distribution device, then it flows continuously through the gap of the packing layer as a counter current with the liquid.

On the surface of the packing, the gas liquid two-phase contact closely for mass transfer. The packed tower is continuous contract gas liquid mass transfer equipment. The two-phase composition changes continuously along the tower height. Under normal operation, the gas phrase is continuous phase and the liquid phase is dispersed phase.

When the liquid flows down the packing layer, it tends to concentrate on the tower wall gradually, which makes the liquid flow near the tower wall increase gradually. This phenomenon is called wall flow. The wall flow effect results in the uneven distribution of gas and the liquid phases in the packing layer, which leads to the decrease of mass transfer efficiency. Therefore, when the packing layer is high, it needs to be segmented and redistributed in the middle. The liquid redistributor consists of liquid collector and liquid redistributor. The liquid flowing from the upper packing is collected by the liquid collector and sent to the liquid redistributor. After redistributing, the liquid is sprayed on the lower packing.

Packed tower has the advantages of large production capacity, high separation efficiency, small pressure drop, small liquid holding capacity and large operation flexibility.

Xintao provide a wide range of chemical packings, such as molecular sieves, activated alumina, ceramic ball and ceramic, metal and plastic random packings.