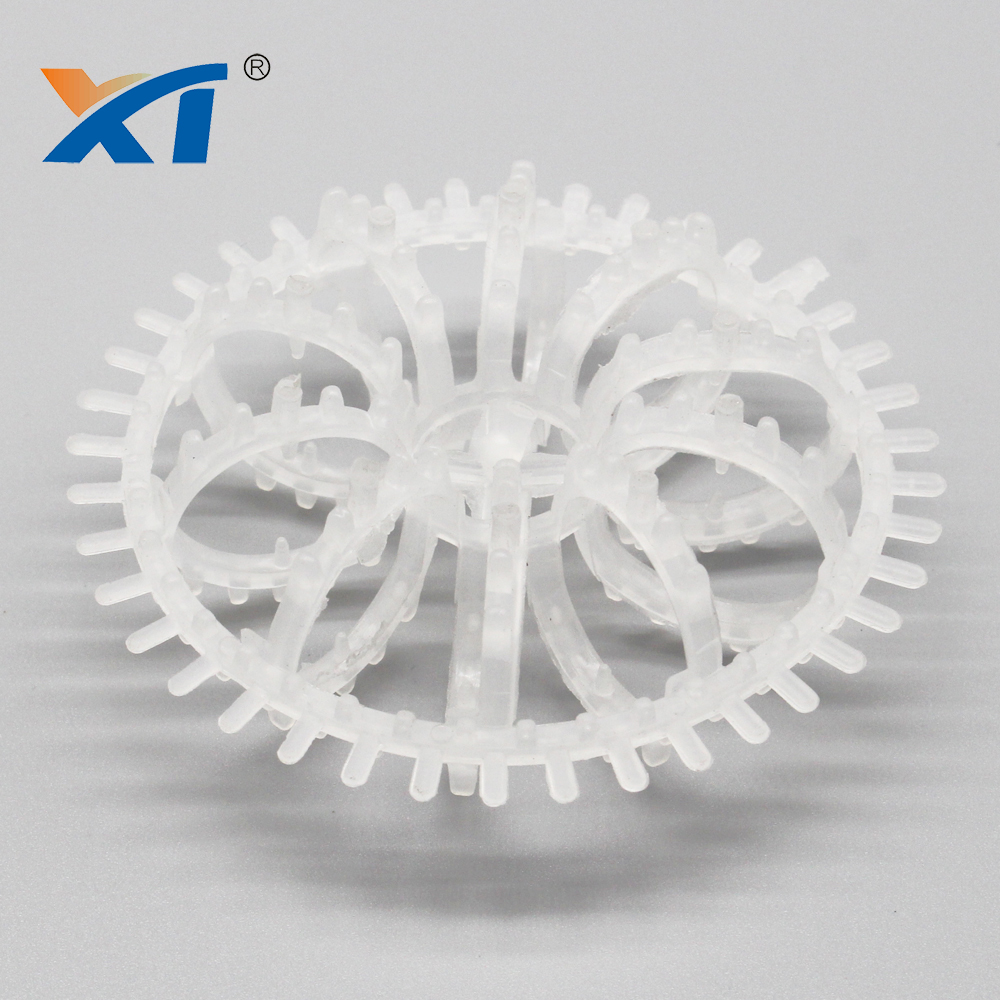

PP Teller Rosette Ring is also called Tellerate Rosette Ring. In addition to polypropylene materials, Tellerate Rosette Ring include polypropylene (PP), polyethylene (PE), enhanced polypropylene (RPP), polyvinyl chloride (PVC), and chloride polyvinyl chloride (CPVC).

Table of Contents

ToggleFeatures of Teller Rosette Ring

The structure of polypropylene Rosette Ring filling does not allow the lower liquid to flow dead corners, and try to increase the comparison surface area of the filler. Because there are many bending branches and binding points, the liquid can be evenly distributed in the filling layer. Plastic flower cycle is large, it is not easy to block, and the volume is large. There are small resistance, and there are more stagnation liquids in the gap, so that the liquid in the tower stays longer, increases the contact time of gas and liquid, and increases efficiency. Its structural characteristics make the packing material pressure very small and can achieve the purpose of energy saving. It is not only resistant to corrosion, but also has good intensity. Because of its light materials and convenient installation. Polypropylene flower rings have a large gap rate, low voltage drop and mass transmission device, high point of general, sufficient air liquid contact, small proportion, and high quality efficiency.

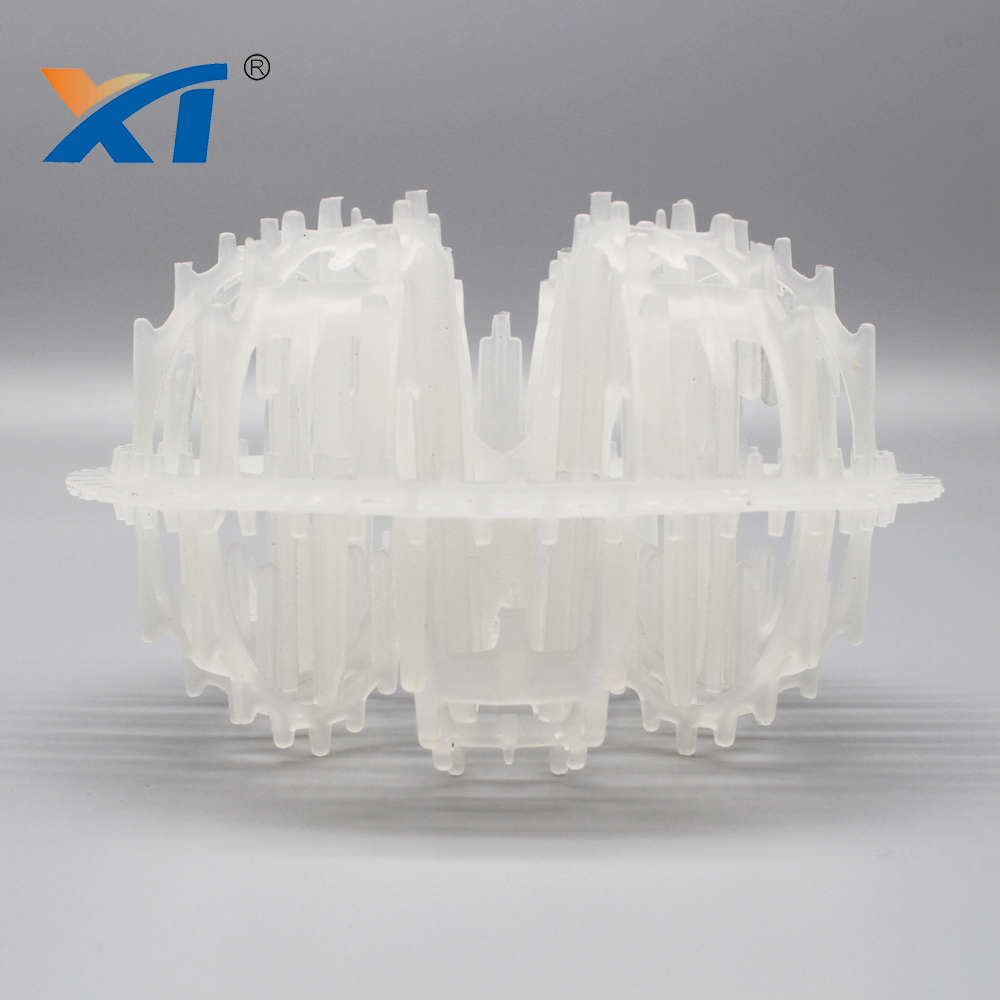

Pp Polypropylene Teller Rosette Ring Filler Application Occasion

Teller Rosette Ring fillers are widely used in acid mist purification tower, spray tower, polypropylene tower, acid mist absorption tower, acid mist washing tower, exhaust gas treatment tower, exhaust gas washing tower, acid washing tower, water washing tower, etc.

Another Kind of Teller Rosette Ring

Teller Rosette Ring Packing, with thorns and rings, can also be called Taylor flower ring fillers, tooth flower ring fillers. Flower ring fillers are an exhaust gas fillers. It is also commonly used in the washing tower for washing layer filler and fog laying filler. The downgraded filling material can be washed and removed when the screw is wrapped together when the solution and sewage pass.

It mainly uses its structural form to be more distributed and contact surface area, and contacts the waste gas or waste liquid to remove the particles in the gas and liquid to absorb harmful corrosive gas. Pour the liquid or gas into the filling bed in the opposite direction when used. After the gases are distributed, the gas is evenly distributed in the ball -shaped Lasi ring. Each of it is exposed to point contact, and the surface area of the contact is used to absorb harmful gases in addition to the particles in the gas and liquid