Table of Contents

ToggleTypes and Applications of Tower Packing

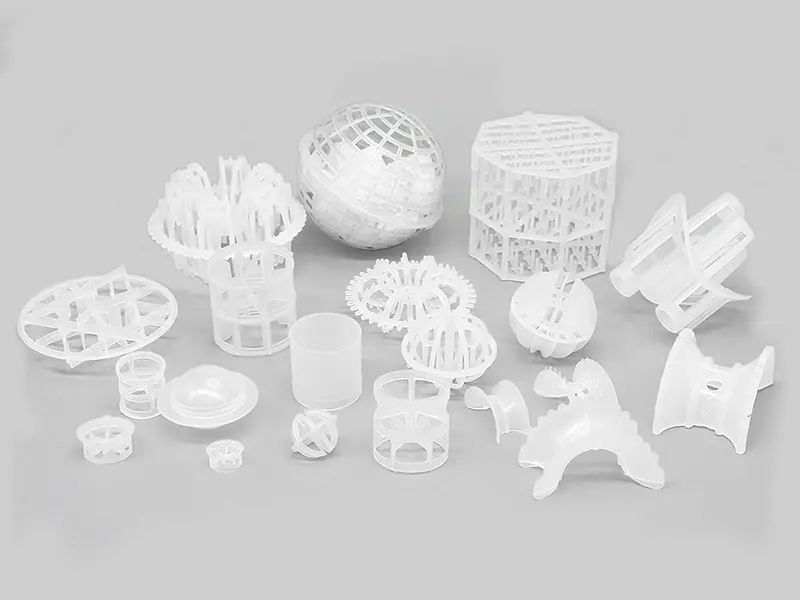

Tower Packing are widely used in the chemical industry and can be used to improve the conversion rate of raw materials and enhance the purity of reaction products. According to different tower packing methods, they can be divided into random tower packing and structured tower packing; according to different materials, common tower packing include ceramic tower packing, metal tower packing, plastic tower packing, etc.

Ceramic Tower Packing

It has the characteristics of high temperature resistance, aging resistance, wear resistance, and corrosion resistance of various inorganic acids, organic acids and organic solvents except hydrofluoric acid. It can be used in drying towers, absorption towers, cooling towers, washing towers, regeneration tower in the chemical, metallurgical, coal gas, oxygen production and other industries.

Metal Tower Packing

It is hard and suitable for reactors that is difficult to process. Metal random and structured packing is made of carbon steel, stainless steel, aluminum alloy and other materials. It has the characteristics of heat resistance, thin wall, large flux, high separation efficiency, etc. It is particularly suitable for vacuum distillation towers and for processing heat-sensitive, easily decomposed, easily polymerized, and easily carbonized materials.

Plastic Tower Packing

It has high mechanical strength, corrosion resistance, and can reduce costs. It is commonly used fillers in chemical production. It is light weight, low cost, corrosion resistance, and high mass transfer efficiency. And it is widely used in packing towers in industries such as petroleum, chemical, chlor-alkali, coal gas, and environmental protection.

Application

In summary, there are many types of tower packing, each with its own unique characteristics and scope of application. It improves process efficiency, improves environmental quality, reduces costs, and improves product performance by increasing contact area, improving flow characteristics, increasing load-bearing capacity, and changing the properties of objects. Understanding different types of tower packing and their characteristics can help engineers choose the right fillers and improve the performance and efficiency of equipment.

Tower Packing

Contact Xintao

If you have any question, please contact us!