Table of Contents

ToggleHow Packed Towers Work?

The function of packed tower is to absorb, and it is one of the most important equipments in chemical industry, petrochemical industry and oil refining production. The packed tower is a mass transfer device in which the packing in the tower is used as a contact member between the gas and liquid phases.

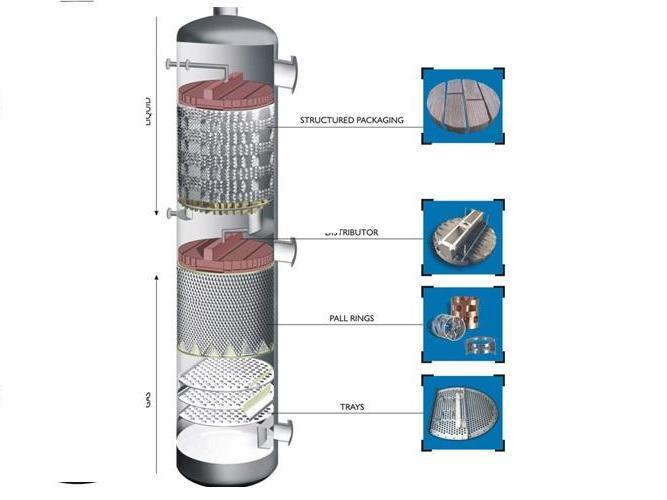

The tower body of the packed tower is a vertical cylinder, and the bottom is equipped with a packing support plate, and the packing is placed on the support plate in a random pile or a whole way. A packing pressure plate is installed above the packing to prevent it from being blown by the updraft.

The liquid is sprayed onto the filler from the top of the tower through the liquid distributor, and flows down along the surface of the filler. The gas is fed from the bottom of the tower, and after being distributed by the gas distribution device (small-diameter towers generally do not have a gas distribution device), it flows countercurrently with the liquid and continuously passes through the gap of the packing layer. On the surface of the packing, the gas-liquid two-phase is in close contact for mass transfer.

The packed tower is a continuous contact gas-liquid mass transfer equipment. The composition of the two phases changes continuously along the height of the tower. Under normal operating conditions, the gas phase is the continuous phase and the liquid phase is the dispersed phase.

When the liquid flows down along the packing layer, there is a tendency to gradually concentrate toward the tower wall, so that the liquid flow near the tower wall gradually increases. This phenomenon is called wall flow. The wall flow effect causes the gas-liquid two-phase distribution in the packing layer to be uneven, thereby reducing the mass transfer efficiency.

Therefore, when the packing layer is high, it needs to be segmented, and a redistribution device is installed in the middle. The liquid redistribution device consists of a liquid collector and a liquid redistributor. The liquid flowing down from the upper layer of packing is collected by the liquid collector and sent to the liquid redistributor. After being redistributed, it is sprayed onto the lower layer of packing.

Contact Xintao

Characteristics of Packed Towers

The packed tower has the advantages of large production capacity, high separation efficiency, small pressure drop, small liquid holdup, and large operating flexibility. The packed tower also has some disadvantages, such as the high cost of the packing; when the liquid load is small, the surface of the packing cannot be effectively wetted, which reduces the mass transfer efficiency; it cannot be directly used for materials with suspended solids or easy polymerization; side feed and Complicated rectification such as discharge is not suitable.

Tower Packing in Towers

Packing is a mass transfer element in a packed column, and it can be classified in different ways. There are two types of packing: Raschig ring saddle packing; Pall ring; Pall ring is a small rectangular window with one or two layers on the wall of the Raschig ring. There are two types of corrugated packing: screen shape and orifice shape.

The basic requirements for the packing are: high mass transfer efficiency, requiring the packing to provide a large gas-liquid contact surface. That is to say, it is required to have a large specific surface area, and the filler surface is required to be easily wetted by liquid. Only wetted surfaces are gas-liquid contact surfaces. Large production capacity and small gas pressure drop. Therefore, the porosity of the filler layer is required to be large. Immobility causes drift and channeling. Durable with good corrosion resistance, high mechanical strength and necessary heat resistance. The material is easy to obtain and the price is cheap.