Table of Contents

ToggleMolecular Sieves for Oil and Gas Separation

Oil and as separation is crucial in the petroleum industry because it helps separate liquid crude oil, high-purity natural gas, recover light hydrocarbons, and remove water, ensuring production efficiency and product quality, as well as further processing and transportation.

Oil and gas separation involves separating the oil and gas mixture (containing oil, gas, and possibly water and solid impurities) produced during oil extraction and refining into its individual components (such as liquid crude oil, natural gas, and light hydrocarbons). The primary goal is to maximize the purity of each component while minimizing energy and time. Effective separation increases productivity and reduces equipment corrosion and wear, which not only protects infrastructure but also improves the efficiency of hydrocarbon recovery, a key element in the current natural gas industry.

Adsorption Separation of Molecular Sieve

Adsorbents, such as molecular sieves, selectively adsorb specific components in oil and gas. Molecular sieve desiccants possess a uniform, well-defined micropore structure whose pores are similar in size to the molecules in oil and gas. When an oil and gas mixture passes through a molecular sieve adsorbent, molecules smaller than the pore size are able to enter and be adsorbed, while molecules larger than the pore size are blocked, effectively separating the different molecules.

Advantages of Molecular Sieves

- High-Efficiency Separation: Enables high-precision separation of different components in oil and gas.

- Energy Savings: Compared to traditional separation methods such as distillation, molecular sieve adsorption separation consumes less energy.

- Mild Operating Conditions: Separation can generally be performed at atmospheric pressure or lower, eliminating the harsh conditions of distillation, such as high temperature and high pressure, reducing equipment investment and operating costs.

- Good Selectivity: Highly selective adsorption for specific oil and gas components effectively removes impurities and improves product quality.

Applications of Molecular Sieves:

- Oil extraction: Wellhead separation (preliminary separation of the oil, gas, and water mixture produced at the wellhead) and gathering and transportation system separation (further purification during pipeline transportation);

- Crude oil refining: Crude oil pretreatment (removing natural gas and impurities to provide qualified feedstock for the distillation unit);

- Natural gas processing: Removing condensate, water, CO₂, and other components from natural gas to meet pipeline transportation or LNG production requirements;

- Light hydrocarbon recovery: Separating propane, butane, and other components from oil and gas to produce LPG or chemical feedstocks.

Contact Xintao

If you have any question, please contact us!

Xintao Molecular Sieve

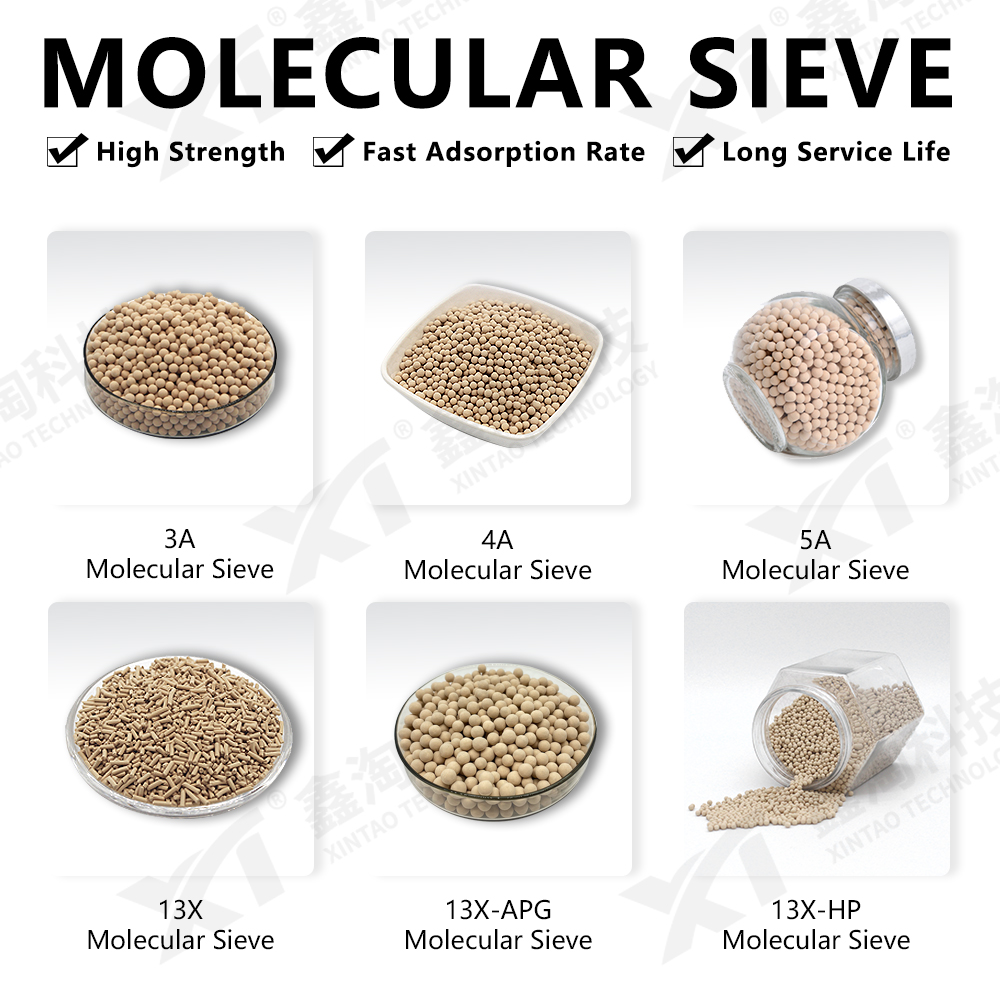

Xintao is a professional molecular sieve manufacturer with 23 years of experience. Its 3A molecular sieve zeolite is used for drying and dehydrating petroleum cracking gases such as ethylene, propylene, and butadiene, as well as for dehydrating natural gas and methane. It is ideal for natural gas dehydration because it does not adsorb hydrocarbons and therefore does not alter the gas composition. 4A molecular sieves can adsorb water from gases and alkanes, while 5A molecular sieves are used for dehydration, removal of sulfur and carbon dioxide, and separation of normal and isoparaffins. Both are particularly effective at adsorbing water and light hydrocarbons, improving gas purity. 13X molecular sieves are widely used for the combined removal of water, carbon dioxide, and hydrogen sulfide.

Due to their unique separation principles, significant advantages, and diverse applications of different zeolite molecular sieve types in oil and gas separation, molecular sieve beads have become an indispensable key technology in oil and gas separation processes, providing strong support for the efficient and green development of the oil and gas industry. With the continuous advancement of technology, the research and development and application of molecular sieve materials will continue to innovate, bringing more breakthroughs and development opportunities to the oil and gas separation field.