Table of Contents

ToggleMolecular Sieve Powder in Honeycomb Panel Structural Adhesives

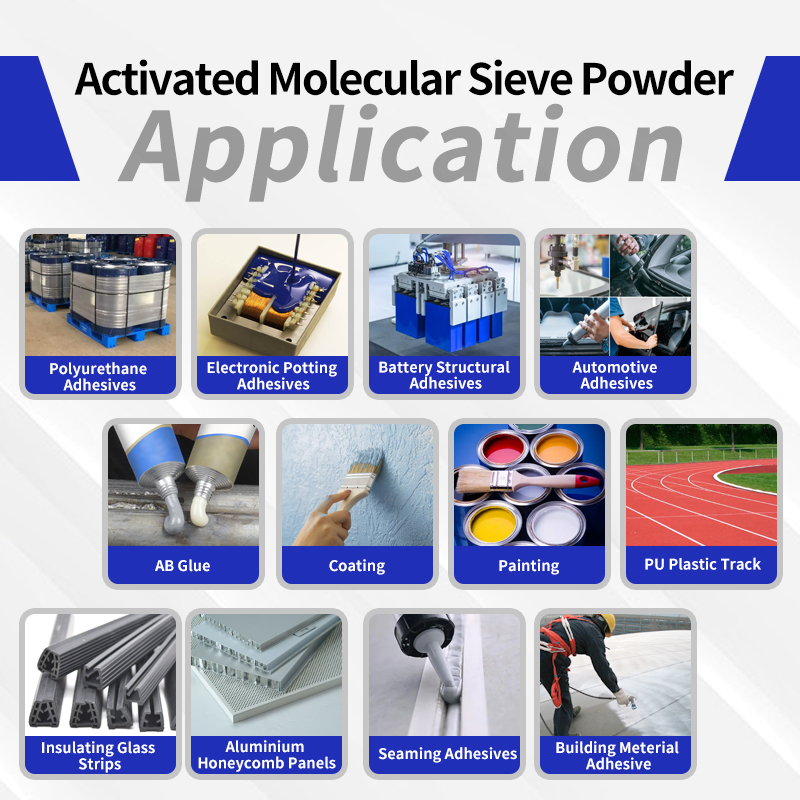

As a leading manufacturer specializing in high-quality molecular sieves, Xintao offers activated molecular sieve powder that demonstrates excellent performance across multiple application scenarios. Among our customer success stories, the use of activated molecular sieve powder as a water remover in building materials, specifically honeycomb panel structural adhesives, represents a significant technical advancement. This innovative chemical material, with its powerful adsorption capacity and molecular selectivity, has become essential in producing two-component polyurethane adhesives and coatings.

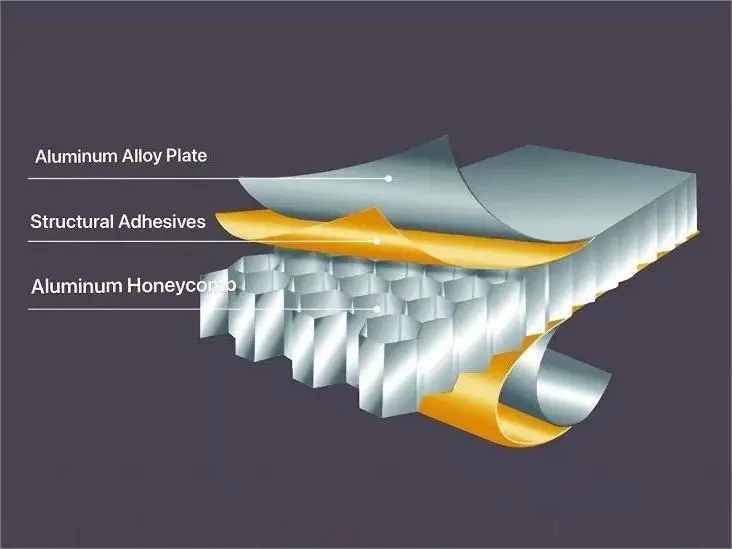

Our client, a manufacturer specializing in honeycomb panel structural adhesives, required an effective solution for simultaneous dehydration and defoaming during production. Honeycomb panel adhesives, recognized as a new generation building material, offer remarkable properties including lightweight construction, high strength, sound insulation, thermal insulation, and fire resistance, making them increasingly popular in construction applications. The production process necessitates incorporating powdered molecular sieves to effectively eliminate moisture and prevent foam formation.

Moisture Impact and Molecular Sieve Advantages

Aluminum Honeycomb Panel Glue utilizes two-component polyurethane adhesive, a solvent-free system where components A and B mix and cure in precise proportions. These components consist of isocyanate-group-rich prepolymers and polyether polyester polyols, primarily reacting through the interaction between isocyanate groups and hydroxyl groups to form polyurethane.

RNCO+Rˊ—OH→RNHCOORˊ

Water Removal and Defoaming

To achieve polyurethane adhesives with superior performance, strict control of moisture in raw materials is essential during synthesis. Molecular sieve materials offer significant advantages in removing trace moisture from solvents. When polyurethane AB component raw materials contain even minimal moisture, isocyanate undergoes hydrolysis and polycondensation upon water contact. This not only disrupts the polyurethane synthesis reaction but also generates numerous dense micro-bubbles within the material.

NCO + H2O → R-NH2 + CO2↑

2R-NCO + H2O → R-NH-CO-NH-R + CO2↑

Bubble Problem Consequences

- These accumulated gas bubbles compromise adhesive continuity and structural integrity

- Increased porosity and internal defects reduce mechanical strength and density

- Surface roughness affects appearance quality

- Reduced contact area with substrates weakens adhesive force

- Bubble entrapment during solidification creates voids and performance degradation

- Bubble rupture may cause stress concentration, inducing micro-cracks and reducing crack resistance

Trace moisture may originate from the materials themselves or absorption from humid environments. Therefore, eliminating trace moisture from raw materials represents the crucial factor in enhancing polyurethane adhesive quality.

Contact Xintao

If you have any question, please contact us!

Xintao Solution: Enhanced Performance with Molecular Sieve Powder

Xintao has collaborated with customers for nearly a year, supplying specialized powdered molecular sieves that deliver exceptional results.

Application Benefits of Activated Molecular Sieve Powder

Molecular sieve powder provides extremely high water absorption precision and strong moisture uptake capability. By adding minimal quantities to raw materials, it enables complete dehydration and drying of polyurethane components – a distinctive advantage that other drying materials cannot match.

The strong water absorption characteristics of Activated Molecular Sieve Powder mean even small additions significantly enhance polyurethane quality. Xintao’s molecular sieve powder offers excellent diffusibility without precipitation, and achieves exceptional purity free from impurities. With over 10 years of application experience in polyurethane synthesis, our product maintains consistently stable quality.

Honeycomb panel two-component polyurethane adhesive incorporating Xintao molecular sieve achieves:

- Smooth, bubble-free surfaces

- Clog-free application

- No bulging or deformation

- Climate change resistance

- High strength performance

- Cost efficiency through high dehydration effectiveness

- Production time savings through rapid processing