How does the molecular sieve dehydration process proceed? Many manufacturers who have drying needs or need to use molecular sieves have doubts about this. This article will introduce molecular sieve desiccant, its working principles, and the dehydration process.

Molecular Sieve Dehydration: How Does it Work

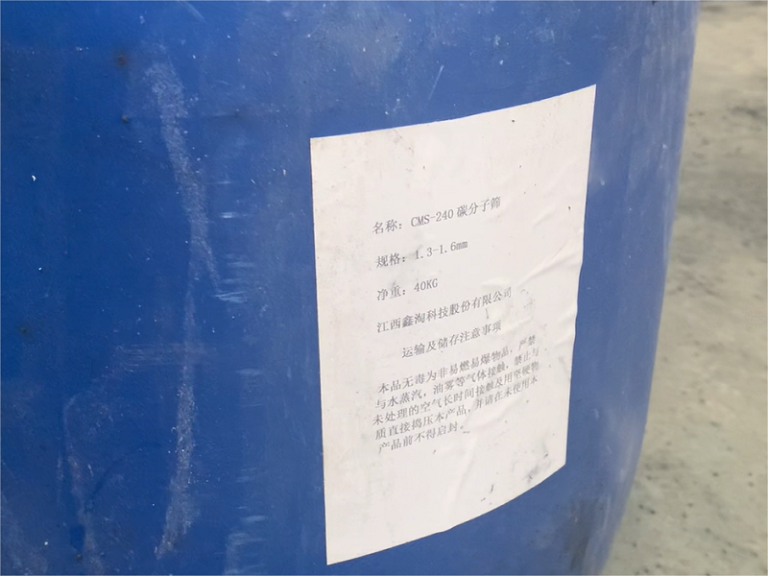

Molecular Sieve Dehydration Desiccant: with a mesh structure of natural or synthetic chemical molecular sieve is a crystalline state of silicate or aluminum silicate, silicon tetrahedron or aluminum silicate tetrahedron connected by oxygen bridge bond, molecular pore size (generally 0.3~2.0 nm) of fine pores and cavity system, and then has the characteristics of screening molecules.

Molecular Sieve Size Classification

Molecular sieve was named because it has the function of separate molecules, so called molecular sieve. 3A molecular sieve, for example, select only the aperture in the following 3a molecular adsorption, and adsorption is bigger than its molecules, so according to the priorities and distinguish between different materials of molecular size, filtering functions is the principle of molecular sieve. However, Must pay attention to the molecular sieve has a strong water imbibition Therefore, the molecular sieve in adsorption regeneration can contact with water, does not reduce the ability of adsorption of co2.

Once accident, water will enter the molecular sieve, can only restore the original special high temperature regenerative adsorption. The adsorption performance principle of molecular sieve adsorption is, in fact, aluminum silicate crystals, the proportion of aluminum silicate, The production of different types of molecular sieve, adsorption or exclusion of crystal pore size of different material molecules, because of the material molecules.

Molecular Sieve Dehydration Process

Molecular sieve desiccant: synthetic desiccant and adsorbent with strong adsorption ability of water molecules. It belongs to industrial adsorbent, the large pore size of molecular sieve molecular sieve is operated by processing technology, not only can adsorb water vapor, but also can adsorb other gases even at a high temperature in the gas purification processing.

Molecular sieve dehydration process: at present, the natural gas dehydration adsorber is mainly used in industry fixed bed adsorption tower, in order to ensure continuous operation of the plant, need at least two molecular sieve adsorption tower process generally fall into two tower, tower process or tower In the process of two tower, a tower for dehydration operation, the regeneration of the adsorbent and cooling tower with another, and then switch operation.

In the three-tower or multi-tower process, the switching program affected by supply conditions and other factors can be selected in a variety of ways. For example, the three-tower process can adopt the switching program of one-tower adsorption, one-tower regeneration, other tower cooling or two-tower adsorption, one-tower regeneration and cooling. The two column flow consists of two columns filled with molecular sieve. It is assumed that tower 2 is dry and tower 1 is regenerating.During regeneration, all adsorbed materials are desorbed by heating to prepare the tower for the next adsorption cycle.

Wet raw material generally after raw material gas filter separator, after removal of carrying droplets, from top to bottom into the molecular sieve dehydration tower tower (2) adsorption process of dehydration After dehydration dry gas after the product is commonly used in gas dust filter dust removal of molecular sieve beads, the product gas as the device sends out the recycling is consists of two parts of heating and cooling

During the heating period, after heating to 200~ 315E with the heater of re-gas and re-gas, enter the molecular sieve dehydrating tower (tower 1) from bottom to top, carry out the molecular sieve regeneration process in the molecular sieve dehydrating tower (tower 1) out of the re-gas and re-gas cooler after cooling, enter the re-gas separator to separate the solidification liquid, Then the gas can enter the wet raw material gas, product gas, the fuel gas system of the factory once the molecular sieve bed regeneration, again gas bypass the heater of the re-gas, into the molecular sieve dehydrating tower (tower 1) cooling bed, cold air outlet temperature is lower than 50E cooling