How is nitrogen generated by molecular sieves? This article will introduce the principle of nitrogen production by loading carbon molecular sieves into PSA nitrogen generators

Table of Contents

ToggleThe First Question, What is Nitrogen?

Nitrogen is an inert, odorless and colorless gas that exists widely in air. It can prevent oxidation reaction, flame retardant, and has many applications in industry.

In order to prevent oxidation of components during assembly and welding of electronic components, nitrogen purging is used. Purging with nitrogen removes oxygen from the air during assembly and also prevents the risk of fire or explosion in some areas.

Nitrogen is also used to prevent slow oxidation, such as the growth of bacteria in pharmaceutical packaging or food.

The level of purity required for nitrogen depends on its use. For most applications, high purity (over 95%) is required.

Due to the continuous expansion of nitrogen application fields, companies are increasingly inclined to produce nitrogen on-site rather than using liquid nitrogen, especially in view of advanced nitrogen production technology, which makes nitrogen more competitive in the market and safer to use.

How Do PSA Generator Seperate Nitrogen?

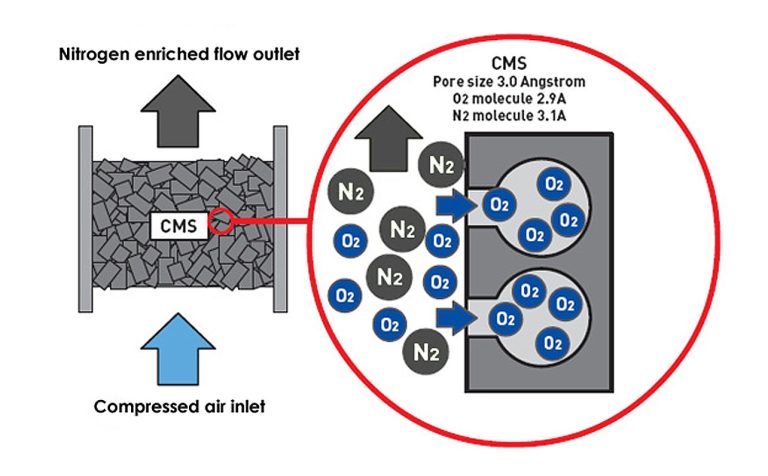

PSA nitrogen generator is based on the principle of pressure swing adsorption, using high-quality carbon molecular sieve as the adsorbent, and adsorbing high-purity nitrogen from the air under a certain pressure. The purified and dried compressed air is subjected to pressure adsorption and decompression desorption in the adsorber, and the pretreated compressed air enters the bottom of the online tower and is followed up by CMS. The CMS preferentially adsorbs oxygen and other trace gases, passing nitrogen through to create a continuous flow of nitrogen. After a preset time, the nitrogen generator automatically switches to regeneration mode to discharge the mixed gas from the CMS.

Nitrogen Generated By Molecular Sieves

Xintao’s carbon molecular sieve for PSA nitrogen generator technology. Purity can even reach 99,999%.

Whether you need the highest purity or lower purity nitrogen, Jiangxi Xintao can provide you with the perfect technical solution.

Xintao’s carbon molecular sieves will be packaged in a very special way to eliminate voids, dust, and act as a compaction. Avoid unfavorable factors that reduce product performance and reduce nitrogen production capacity.

Finally, according to your needs, choose the right Xintao carbon molecular sieve for your PSA nitrogen generator.

Be sure to work with your professional manufacturer to ensure that the material you choose will provide you with the best functionality and value.

If you have any needs, please contact us, we will provide you with continuous professional services.