Table of Contents

ToggleHow Does Oxygen Molecular Sieve Work in Oxygen Generator?

Molecular sieve is adsorbents with a uniform microporous structure. The pore size is comparable to that of molecules, enabling them to selectively adsorb molecules based on their shape, size, and polarity. 13X HP molecular sieve and lithium molecular sieve are commonly used in oxygen generator.

Oxygen Molecular Sieve

13X HP molecular sieve is a sodium aluminosilicate with a large pore size and adsorption capacity. It has a strong adsorption capacity for nitrogen and can efficiently separate oxygen and nitrogen from air under certain conditions. Lithium molecular sieves are modified from 13X HP molecular sieves through lithium exchange. They offer even better adsorption performance, especially in high humidity and high temperature environments. This significantly improves the efficiency and stability of oxygen generators.

13X HP Molecular Sieve

Lithium Molecular Sieve

Operating Principle

Oxygen generators utilize pressure swing adsorption (PSA) technology, taking advantage of the molecular sieve desiccant’s selective adsorption of different gas molecules and the pressure-dependent changes in this property. A compressor compresses air and sends it into an adsorption tower. Under high pressure, the molecular sieve preferentially adsorbs nitrogen and other impurities, enriching oxygen for output. When adsorption reaches a certain level, the tower is depressurized, weakening the molecular sieve’s nitrogen adsorption capacity. The nitrogen is then discharged, allowing the molecular sieve to regenerate.

Oxygen Molecular Sieve Advantages

Xintao oxygen molecular sieves primarily consist of 13X HP zeolite molecular sieve and lithium zeolite molecular sieve, primarily used in pressure swing adsorption(psa) oxygen concentrators. They offer excellent chemical and thermal stability, a wide range of pore sizes, a large specific surface area, and a superior nitrogen-oxygen separation coefficient. They rapidly and efficiently adsorb nitrogen, producing high-purity oxygen. Zeolite molecular sieve desiccants for oxygen production can achieve oxygen concentrations as high as 96%.

Applications

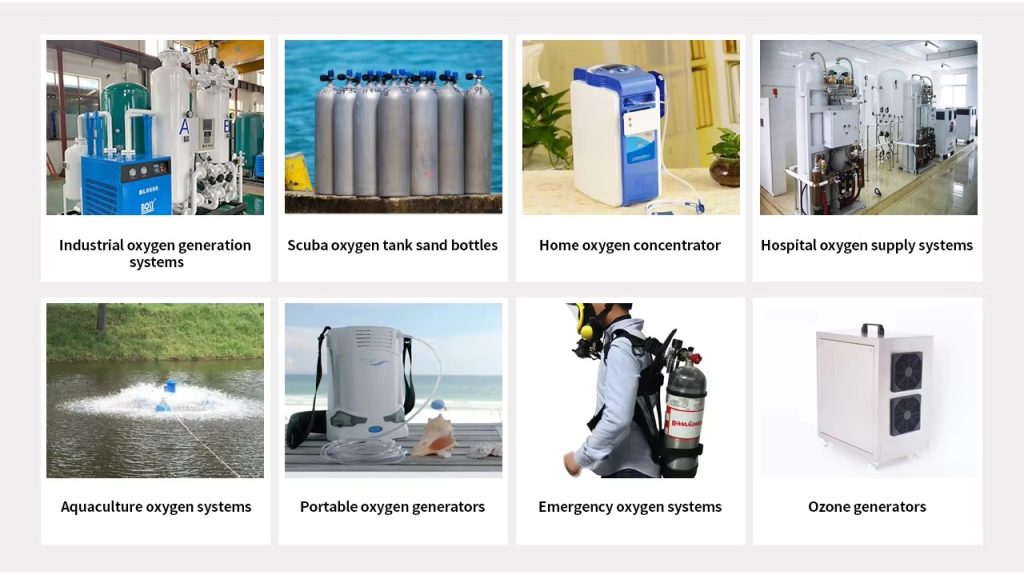

Oxygen concentrators play a vital role in many applications, including chemical processing, healthcare, home care, and high-altitude environments. For example, in industrial processes such as metal cutting and welding, oxygen is required as a combustion-supporting gas to increase flame temperature and ensure production quality and efficiency. Molecular sieve oxygen concentrators are essential in hospital emergency rooms, ICUs, and respiratory departments, and are even used to ensure continuous oxygen supply during surgery to stabilize patients’ vital signs. They can also be used for home oxygen therapy and health care. For the elderly, those with weak constitutions, and those with sleep apnea, home oxygen concentrators can provide an appropriate amount of oxygen for daily life. Furthermore, high altitude areas, with their low oxygen levels, are prone to altitude sickness. Portable molecular sieve oxygen concentrators can rapidly generate oxygen, providing oxygen to stationed personnel, patients, and tourists, alleviating discomfort and ensuring their health and safety.

Contact Xintao

If you have any question, please contact us!