Table of Contents

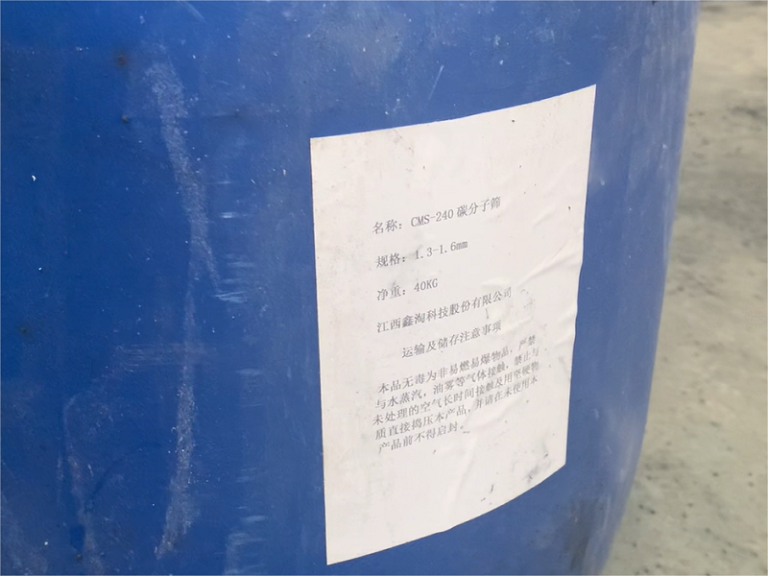

ToggleXintao Food Preservation CMS Carbon Molecular Sieve: The Core Guarantee of PSA Nitrogen Production Technology

In the field of food preservation and green storage and transportation, nitrogen has become an indispensable protective gas due to its inert characteristics. It can effectively inhibit pests and diseases in granaries, prolong the freshness of fruits and vegetables, and ensure the quality of nitrogen-filled packaging. It is widely used in green grain storage, wine sealing, seafood preservation, and food nitrogen expansion. The CMS carbon molecular sieve developed by Xintao Technology specifically for the food industry is the core material for efficient and economical nitrogen production.

Intelligent Nitrogen Production: PSA Technology Enables Food Preservation

The Xintao food preservation nitrogen production system is based on the principle of pressure swing adsorption (PSA). It achieves nitrogen and oxygen separation through the precise screening of compressed air by carbon molecular sieves:

High-efficiency adsorption separation: Compressed air (0.7~0.8MPa) enters the adsorption tower. The carbon molecular sieve preferentially adsorbs oxygen with a fast diffusion rate due to its unique microporous structure, and high-purity nitrogen is enriched and output.

Intelligent regeneration cycle: at the moment of depressurization, the adsorbed oxygen is quickly desorbed and discharged, the molecular sieve is automatically regenerated, and the microcomputer control ensures the continuous and stable operation of the process.

This technology provides dry, pure and continuous nitrogen sources for food packaging, beverage processing, fruit and vegetable storage and other scenarios, with core advantages such as rapid start and stop, controllable purity, energy saving and consumption saving, and flexible mobility.

Food-Grade Nitrogen Standards And Xintao Solutions

Food preservation usually requires nitrogen purity ≥ 98%. Xintao CMS carbon molecular sieve can stably produce nitrogen with a purity of up to 99.999%, far exceeding the basic needs of the industry. Its excellent performance is reflected in three core values:

Cost reduction and efficiency improvement: PSA process nitrogen generation is fast and energy consumption is low, which greatly reduces the cost of preservation

Stable purity: real-time instrument monitoring to ensure that the nitrogen purity always meets the process standards

Long-term reliability: high adsorption capacity, strong pressure resistance, significantly extending the life of the sieve

Why Choose Xintao CMS Carbon Molecular Sieve?

▶ Designed for food processing to eliminate contamination risks

▶ Precise microporous structure control to improve oxygen separation efficiency

▶ Strong resistance to airflow impact to avoid purity fluctuations caused by pulverization

▶ Longer life than similar products, and optimized per-ton preservation cost