Claus sulfur recovery catalyst is a special catalyst for Claus sulfur recovery tail gas treatment. It is a catalyst made of alumina or titanium oxide as a carrier, with transition metal active components added and a special production process. It is insoluble in water and organic solvents, and does not expand or break after absorbing water.

Xintao sulfur recovery catalyst has high catalytic activity, can effectively promote the sulfur recovery reaction, make the conversion rate of two-stage Claus greater than 96%, can improve the sulfur recovery rate, reduce the waste of sulfur resources, and has a large specific surface area to provide more active sites for the catalytic reaction, which is conducive to the adsorption of reactant molecules and the reaction, thereby improving the catalytic efficiency.

At the same time, it also has good anti-sulfation performance and thermal stability. During long-term use, it can maintain stable catalytic performance, is not easy to be deactivated due to changes in reaction conditions, and has a long service life. Xintao Claus catalyst can effectively remove sulfides such as hydrogen sulfide in exhaust gas, so that the discharged exhaust gas meets environmental protection standards and reduces pollution to the environment.

Xintao can provide you with TiO2 titanium-based sulfur recovery catalyst and cobalt-molybdenum type catalyst. The former uses titanium dioxide as a carrier, has good catalytic activity and selectivity, can achieve efficient sulfur recovery at a lower temperature, and is suitable for sulfur recovery devices of various sizes. The latter belongs to cobalt-molybdenum type catalyst, which is mainly used for hydrogenation treatment of sulfur tail gas, converting sulfur dioxide and other sulfides in tail gas into hydrogen sulfide, and then recovering sulfur, which can improve the overall efficiency of sulfur recovery.

Xintao catalyst has a wide range of applications, and the specific applications are as follows:

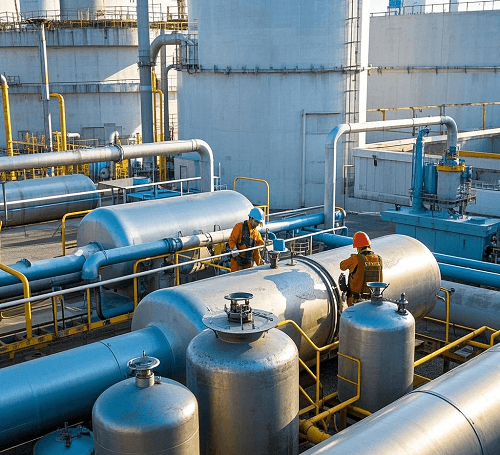

Refinery: It can be used to treat hydrogen sulfide acid gas generated during the refining process, recover sulfur, reduce environmental pollution, and realize the recycling of sulfur resources.

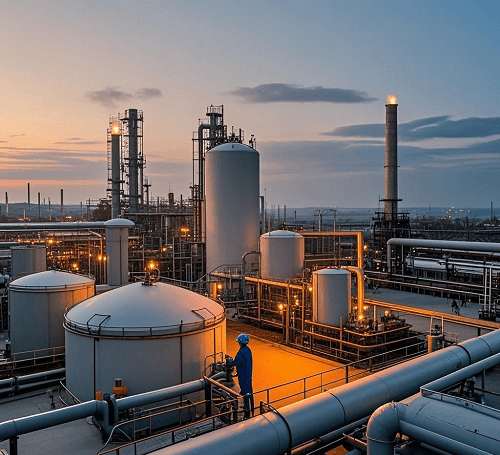

Natural Gas Purification and Desulfurization Plant: During the natural gas purification process, hydrogen sulfide and other sulfides in natural gas are removed and converted into sulfur, improving the quality of natural gas and meeting industrial and civilian needs.

City Gas Plant: treat sulfides in city gas, recover sulfur, reduce the sulfur content in gas, reduce atmospheric pollution during combustion, and improve the quality of gas.

Chemical Plant: Xintao catalyst is used to treat sulfur-containing waste gas generated in various chemical production processes, to achieve sulfur recovery and standard emission of waste gas, to protect the environment and reduce production costs.