Nitrogen carbon molecular sieve (CMS) adopts nitrogen production process at room temperature and low pressure respectively for nitrogen filling, compared with the previous low temperature and high pressure nitrogen production process, low investment cost, fast nitrogen production speed molecular sieve is an excellent non-polar carbon information.

Table of Contents

ToggleXintao Carbon Molecular Sieve: The Excellence Core of Tire Nitrogen Filling System

In the field of tire nitrogen filling, an efficient and stable nitrogen source is essential.

Xintao carbon molecular sieve (CMS) is the core driving force for modern tire nitrogen filling machines to achieve high-performance nitrogen production.

Core Technology: Carbon Molecular Sieve Pressure Swing Adsorption (Psa) Nitrogen Production

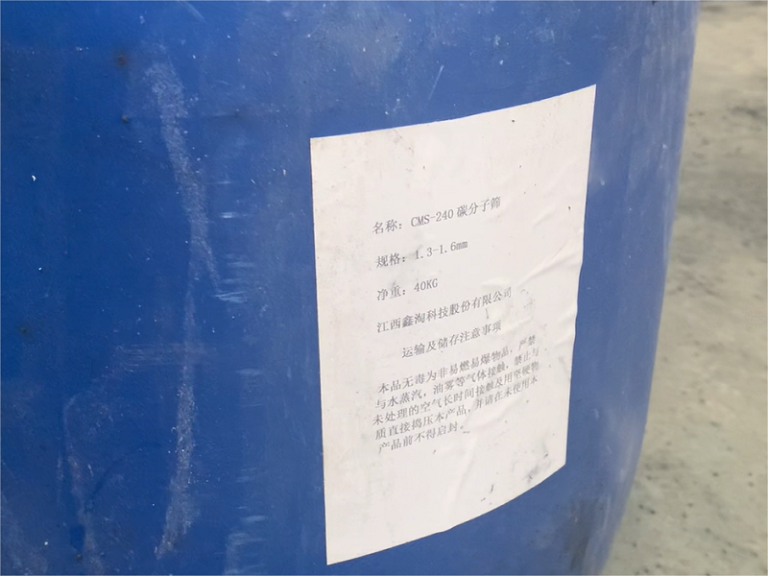

Xintao carbon molecular sieve (such as CMS-240, CMS-260, CMS-280, CMS-300, CMS-330) uses its unique microporous structure to show extremely high adsorption rate and selectivity for oxygen molecules during pressure swing adsorption. When compressed air flows through the adsorption tower filled with Xintao molecular sieve:

High-speed oxygen adsorption: Oxygen molecules are quickly and massively adsorbed and captured by the carbon molecular sieve.

Nitrogen enrichment: Nitrogen molecules are adsorbed slowly, so they can be enriched in the gas phase and directly produce high-purity nitrogen.

Efficient regeneration: When the adsorption tower is depressurized to normal pressure, the adsorbed oxygen is quickly desorbed and released, and the carbon molecular sieve is instantly regenerated to prepare for the next adsorption cycle.

This cyclic process of rapid switching between pressurized adsorption and decompression desorption (usually using a dual-tower parallel design) ensures continuous and stable production of nitrogen.

Tire Nitrogen Filling: Performance And Safety Guarantee

Due to its unique physical and chemical properties, nitrogen is an ideal choice for high-end tire filling:

Stabilize tire pressure: Nitrogen has a low thermal expansion coefficient (about 50% lower than air), is less affected by temperature, can maintain the optimal tire pressure for a longer time, and improve handling stability and fuel economy.

Reduce the risk of tire blowout: The combination of stable tire pressure and extremely low permeability of nitrogen (about 90% lower than air) significantly reduces the chance of tire blowout caused by abnormal increase in tire pressure.

Extend tire life: Dry nitrogen delays rubber aging and reduces rim oxidation corrosion, thereby extending the service life of tires and wheels.

Optimize performance: Improve the shock absorption elasticity of the tire, enhance the ground adhesion during driving, and reduce noise and vibration.

Xintao Carbon Molecular Sieve: A Reliable Choice for Tire Nitrogen Production

Xintao Technology focuses on the research and development and production of high-performance carbon molecular sieves. Our tire nitrogen production special molecular sieves (such as CMS-240, CMS-260) have won the trust of customers with their significant advantages:

Excellent performance: Excellent oxygen and nitrogen separation efficiency, easily producing 99.5% to 99.99% high-purity nitrogen, meeting the stringent tire nitrogen filling requirements.

High physical strength: High hardness and uniform particles, effectively resisting airflow impact, ensuring the stability of the adsorption bed and extending the service life.

Low ash content, high cost performance: Low impurity content, stable performance and slow decay, providing customers with a longer service life and better comprehensive cost-effectiveness.

Choose Xintao, choose an excellent nitrogen source.

Xintao carbon molecular sieve is an ideal partner for tire nitrogen filling machine manufacturers and operators. We are committed to providing high-performance and high-reliability core adsorption materials to provide solid nitrogen guarantees for global tire safety and performance improvement.