Table of Contents

ToggleExhibition Participation: Showcasing Adsorbent Solutions

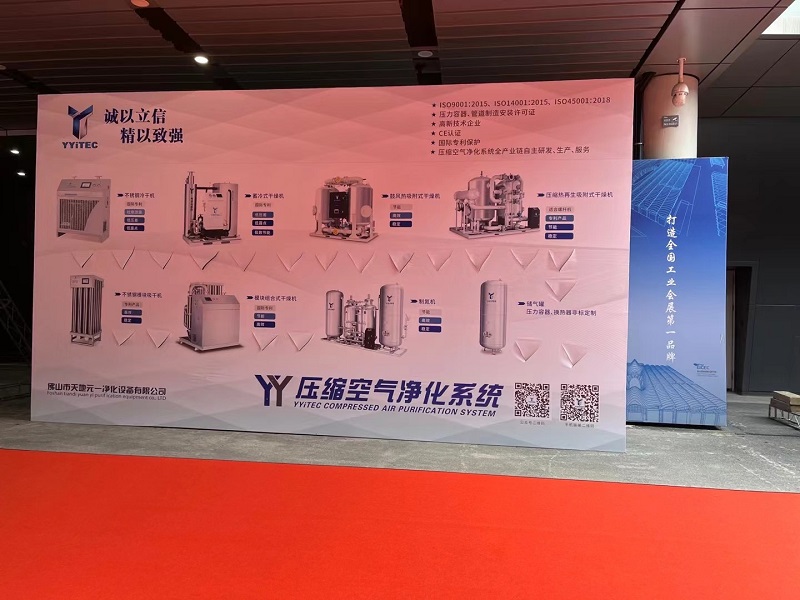

From May 15-18, 2023, Xintao Technology proudly participated in the South China Air Compressor Exhibition, a significant industry gathering that brought together air compressor manufacturers and suppliers from across China. As a specialized supplier of air separation adsorbents, Xintao showcased its core product lines including molecular sieves, activated alumina, and ceramic balls to professionals throughout the air compressor industry.

The exhibition provided an excellent platform for Xintao to demonstrate its technical expertise and connect with customers from various regions. The event highlighted the industry’s continuous drive for innovation, reinforcing Xintao’s commitment to advancing adsorption technology. With 21 years of experience as a renowned molecular sieve brand, Xintao remains dedicated to reaching new heights through ongoing innovation and quality improvement.

Adsorbents in Air Compression Systems

The growing air compressor industry serves numerous sectors including manufacturing, healthcare, mining, and construction. Molecular sieve adsorbents play crucial roles in ensuring optimal air compressor performance through several key applications:

1.Moisture Separation

Air contains a certain amount of moisture. If compressed directly, this moisture will generate vapor, which can affect the proper functioning of the air compressor. Therefore, a molecular sieve adsorbent is installed at the air compressor inlet to separate the moisture. Molecular sieve adsorbents, with their unique pore structure, rapidly absorb moisture from the air, thereby improving the dryness of the compressed air.

2.Oil Separation

During operation, oil enters the compressor along with the compressed air. If this oil is not effectively treated, it can contaminate pipes, valves, and other equipment within the air system, impacting proper operation. Therefore, installing a molecular sieve adsorbent in the air compressor effectively separates the oil and ensures the purity of the compressed air.

3.Gas Drying

In some special applications, compressed air must be free of moisture and impurity molecules. In these cases, a molecular sieve adsorbent is installed at the air compressor outlet to further adsorb the compressed air. Molecular sieve adsorbent uses its special pore structure to efficiently adsorb gases such as moisture, carbon dioxide and hydrogen sulfide in the air, thereby ensuring the purity and dryness of the air.

Xintao Adsorbent

Xintao's Technical Advantages

As a professional molecular sieve manufacturer with two decades of experience, Xintao Technology produces adsorbents widely used in air compressors, liquefied gas, hydrogen purification and related fields. Our products utilize high-quality raw materials, advanced production processes, and state-of-the-art automated equipment to deliver exceptional performance characteristics including high strength, pressure resistance, and long-term durability.

Xintao’s molecular sieve adsorbents have become increasingly essential for ensuring smooth air compressor operation, with our proprietary formulations establishing market leadership through superior product quality and comprehensive technical support services.