Jiangxi Xintao Technology Co., Ltd.

There is chemical industry there is Xintao chemical packing.

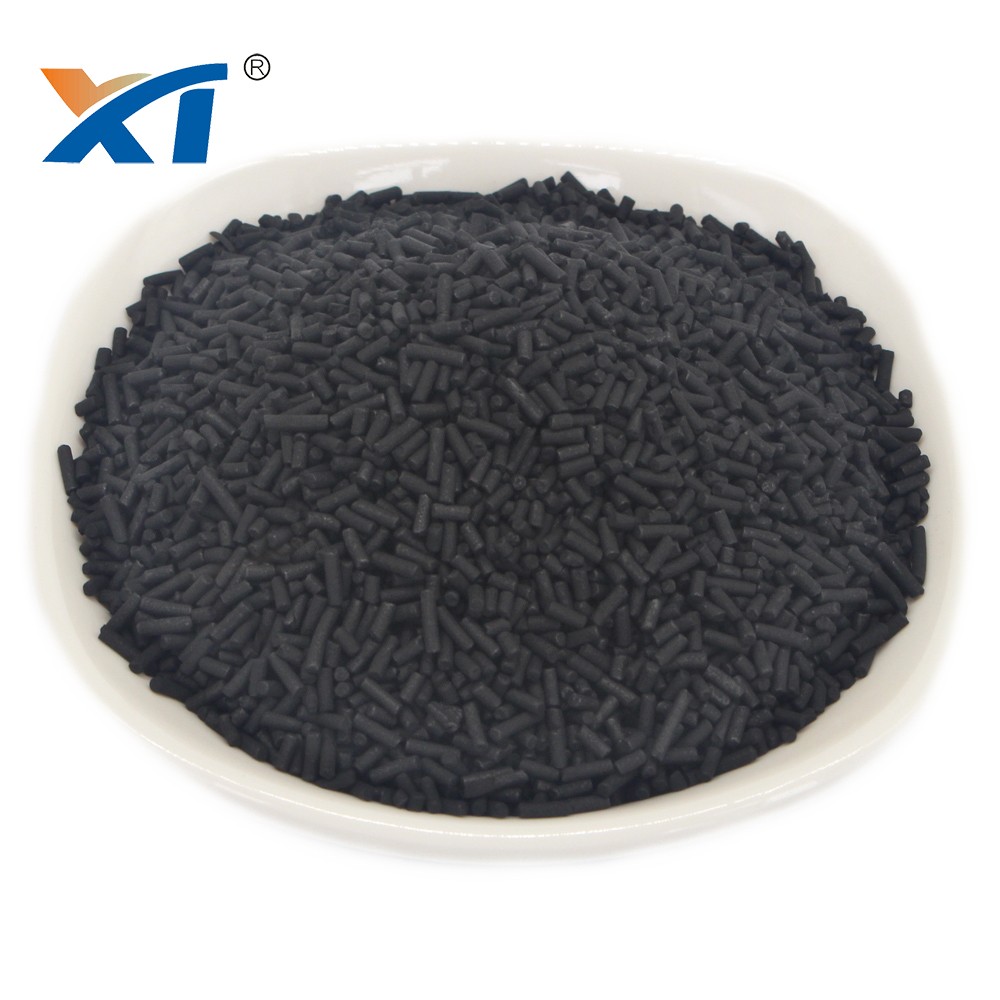

What is carbon molecular sieve adsorption

Carbon molecular sieve is a non -polar carbon material. Making nitrogen carbon molecules is used to separate air and enriches nitrogen. The use of room temperature and low pressure nitrogen technology has the advantages of low investment cost, fast nitrogen production speed, and low nitrogen cost.

Working principle of carbon molecular sieve

Carbon molecular sieve is the purpose of separating oxygen and nitrogen by using the characteristics of sieveing. When the molecular sieve attach impurities gas, the large pores and middle holes only play a channel, and the adsorbent molecular is transported to the micropores and sub -pores. Micro -holes and sub -holes are real adsorption volumes. Carbon molecular sieve contains a large amount of micropores, allowing small dynamic molecules to quickly spread to the holes, limiting the entry of large diameter molecules. Because the relative diffusion rate of different sizes of gas molecules can be separated, the composition of the gas mixture can be separated. When making a carbon molecular sieve, according to the size of the molecular siege, the micro -hole distribution in the carbon molecular sieve should be 0.28 ~ 0.38nm. In the range of micropores, oxygen can be quickly spread to the hole through micropores, and nitrogen is difficult to achieve oxygen and nitrogen separation through micropores. Microscopic diameter is the basis of carbon molecule sieve separation oxygen and nitrogen. If the pore diameter is too large, the oxygen and nitrogen molecular sieve can easily enter the micropore and cannot be separated; if the pore diameter is too small, the oxygen and nitrogen cannot enter the micropore and cannot be separated.

The raw materials of carbon molecular sieve are coconut shells, coal, resin, etc., first processing and then powdering, and then blending with the substrate. The substrate is mainly to increase the intensity and prevent crushing powder from; the second step is to activate hole -made, and to pass the activist at a appropriate temperature. They have armal chemical reactions with relatively lively non -fixed -alphaly carbon atoms to expand the surface area and gradually form a hole of 10 ~ 60min. The third step is to adjust the pores structure, and the chemical steam is used: such as benzene sinks on the carbon molecular sieve micropore wall, adjust the size of the pores to meet the requirements.

E-mail: export@xt988.com

Copyright © Jiangxi Xintao Technology Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a responsefrom us via email. Please be sure to leave yourcontact details so that we can better assist