Table of Contents

ToggleType of Molecular Sieves for Sulfur Removal

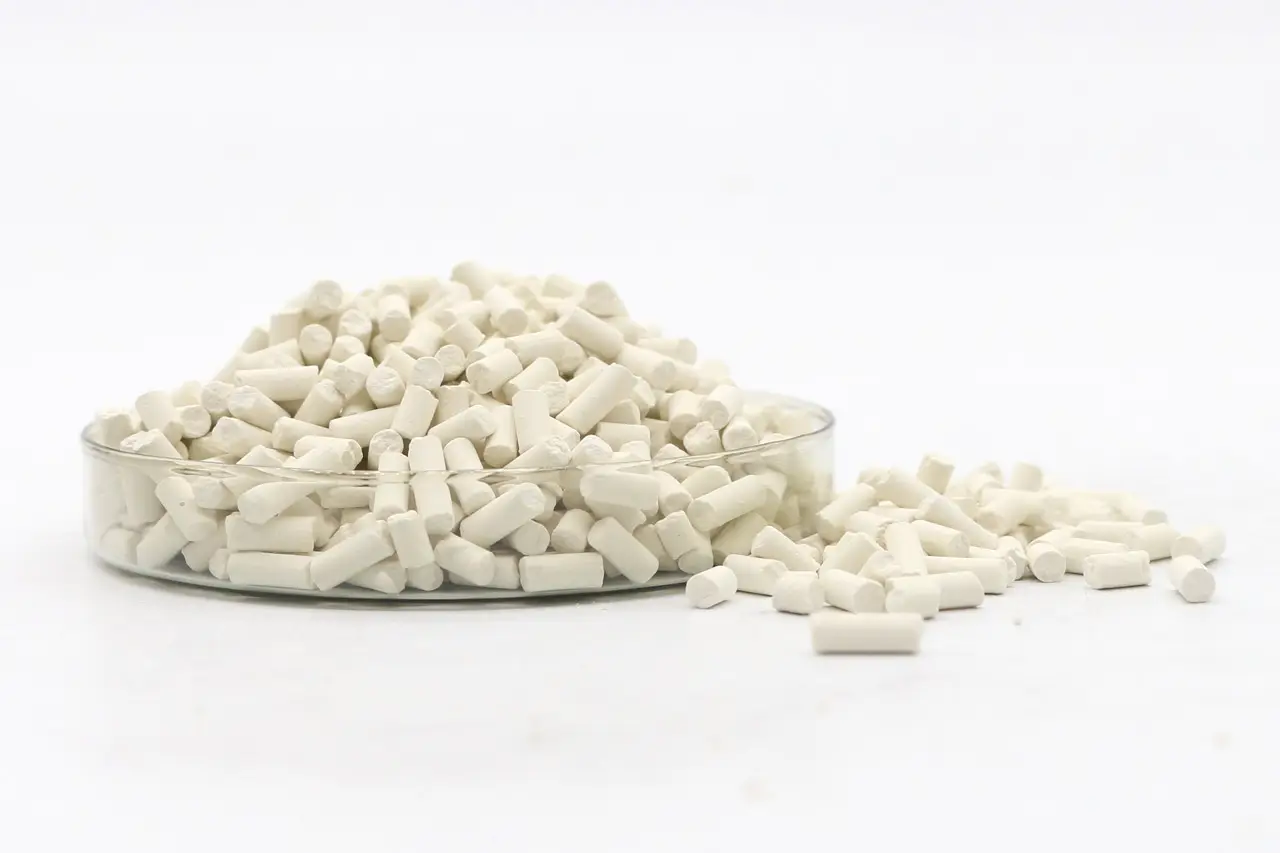

Molecular sieves 5A and 13X are commonly used for desulfurization (5A for light sulfur while 13X for heavy and branched sulfur species). Type 13X molecular sieve has larger pore openings and therefore has better kinetics than type 5A; however, coadsorption of BTX (benzene, toluene, and xylene) components, which can block pores and deactivate the molecular sieve, may hinder heavy mercaptans removal. It is sometimes better to use a compound bed with successive layers of molecular sieves for adsorbing the different impurities. This combination increases the useful capacity of the bed, which is typically the case when water, H2S, mercaptans, and other sulfur species need to be removed at the same time.

Regeneration Method and Steps

Temperature swing adsorption (TSA) is used to regenerate a molecular sieve bed in both natural gas and hydrocarbon liquids’ drying and treating applications to meet stringent product specifications. In this method, the change in the adsorption equilibrium is obtained by increasing the temperature.

To regenerate the molecular sieve in liquid-phase applications such as LPG treating, below steps are generally involved :

- Depressurization

- Draining

- Purging

- Heating

- Cooling

- Repressurization and Standby

Note: typical cycle time for an LPG treating unit consisting of 3 molecular sieve vessels is 24 hr including 8 hr of adsorption, 8 hr of standby and 8 hr of regeneration (draining, heating and cooling).