Table of Contents

ToggleSolutions for Efficient Dehydration of Ethanol

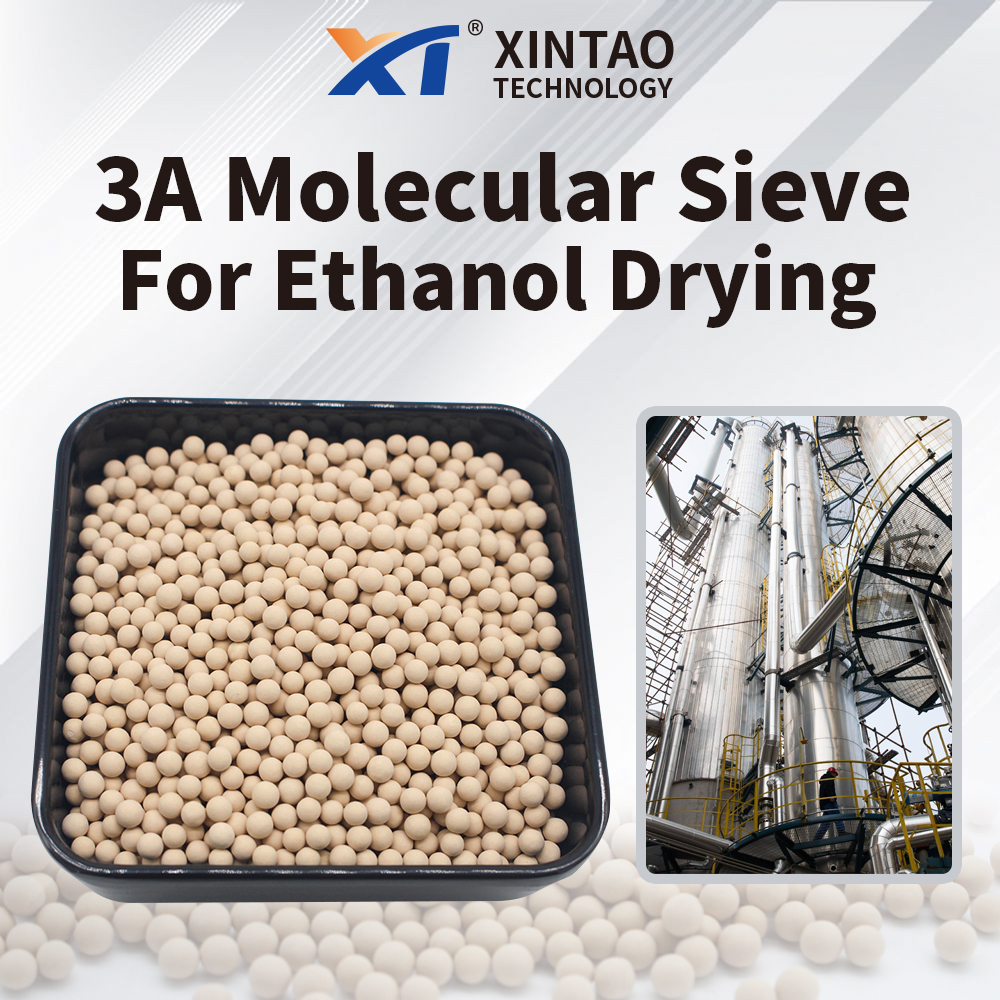

With the widespread application of bioethanol as a clean energy source, the “deep dehydration” link in its production process has put forward higher requirements for the performance of adsorption materials and technical service capabilities. Xintao 3A molecular sieve successfully completed the distillation tower filling project for a bioethanol company.

Customer Situation

The customer purchased 60 cubic meters of 3A molecular sieves and 4 cubic meters of porcelain balls, which are planned to be used in the bioethanol dehydration process. In response to customer needs, Xintao responded quickly and dispatched a professional technical team to the customer’s factory to provide detailed and professional filling guidance services throughout the process to ensure the smooth progress of the project.

Filling Guidance Work

Before filling: Xintao technicians checked the cleanliness of the inner wall of the ethanol distillation tower and the integrity of the supporting structure to eliminate the risk of molecular sieve leakage. Secondly, they carefully debugged the equipment to ensure that 60 cubic meters of molecular sieves can be poured into the tower smoothly.

During loading: First, a layer of 13mm porcelain balls is laid at the bottom of the distillation tower to form a supporting bed layer, evenly distribute the inlet fluid, and prevent the molecular sieve from leaking. Then, a layer of 6mm porcelain balls is laid as a transition layer to fill the gaps between the large balls, build a flat supporting surface, and avoid local pressure on the molecular sieve. Secondly, the molecular sieve is filled. 60 cubic meters of 3A molecular sieve is lifted by a crane and slowly poured into the tower. The lifting process adopts the “multi-point material laying + shock compaction” process to control the filling density at 650-680kg/m³ to eliminate the bridging effect. Finally, 6mm small porcelain balls and 13mm porcelain balls are laid on the top as a protective layer to buffer the impact of airflow, intercept upstream impurities, and extend the service life of the molecular sieve.

After loading: After checking that the equipment is installed normally, the technical members conduct on-site sampling and testing. The molecular sieve can absorb water efficiently and the water absorption rate is greater than 21%. The customer is very satisfied with the result.

Advantages

In bioethanol production, Xintao 3A molecular sieve has shown many advantages, such as its high selective adsorption, only adsorbing water molecules, not ethanol molecules, ensuring that the purity of ethanol reaches more than 99.5%; 3A zeolite molecular sieve has a strong affinity for water and can absorb water efficiently. After laboratory and industrial scene verification, the static water absorption rate exceeds 21%, significantly improving the processing capacity of a single adsorption cycle and reducing regeneration energy consumption; in addition, it has high mechanical strength and thermal stability, as well as a long service life.

Consult Xintao Molecular Sieve

Xintao Installs Molecular Sieve for Customers