Table of Contents

TogglePolyurethane Adhesives: Why Are Powdered Desiccant Preferred?

From September 17th to 19th, 2025, at booth W2372 at the Shanghai New International Expo Center, Xintao Technology will explore how activated molecular sieve powder can solve the problem of bubbles in polyurethane adhesives, improving product performance and market competitiveness.

About Exhibition

During the polyurethane adhesive production process, trace amounts of moisture react with isocyanates to produce CO₂ gas, which can cause bubbles in the product, compromise bond strength, and even lead to surface roughness and performance degradation. Efficiently removing moisture from polyurethane systems is critical to ensuring product quality. Currently, dehydration solutions in the industry fall into three main categories: high-temperature distillation, liquid dehydration agent addition, and the use of powdered desiccant such as activated molecular sieve powder. However, based on compatibility, efficiency, and safety, powder activated molecular sieve is becoming the mainstream choice.

At the upcoming 28th China International Adhesives & Sealants Exhibition, Xintao Technology will showcase its comprehensive line of powder molecular sieves, including 3A, 4A, 5A, 13X, and modified activated molecular sieve powder. We have assembled a dedicated exhibition team, including sales representatives, technical experts, and R&D engineers, to provide comprehensive technical support and solutions. We sincerely invite new and existing customers to visit booth W2372 for a face-to-face discussion and discuss why powdered desiccants are the optimal choice for dehydration and defoaming in polyurethane systems.

High-Temperature Distillation Dehydration Method:

The core principle of high-temperature distillation is to vaporize water through heating, then condense and recover the water. This method is suitable for dehydrating large amounts of solvents. While it effectively removes water, it is not suitable for temperature-sensitive polyurethane systems.

- High energy consumption and operating costs.

- High temperatures may cause chemical changes in polyurethane components.

- Cannot be used in pre-formulated polyurethane systems.

- Can only process liquid components, limiting its applicability.

Liquid Dehydration Agent Method:

Liquid dehydrators (such as isocyanate monomers and organotitanium compounds) consume water from the system through a “chemical reaction.” They are commonly used in the mixing stage of two-component polyurethane adhesives, but they have some limitations. May participate in the polyurethane reaction, affecting the product’s chemical structure.

- Introducing new chemical components may cause side reactions.

- Residual moisture may affect the final product’s performance.

- Limited water removal efficiency, making deep dehydration difficult.

- More expensive than other methods.

Powdered Desiccant - Activated Molecular Sieve Powder:

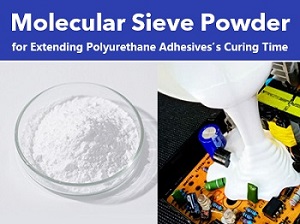

Activated molecular sieve powder is a white powder formed by deep processing and activation of synthetic molecular sieve powder. During high-temperature calcination, the raw molecular sieve powder loses moisture, resulting in a strong adsorption capacity. Powder molecular sieve has a high specific surface area and abundant microporous structure, enabling rapid dehydration of polyether polyols. By removing moisture, it blocks the reaction between water and isocyanate to produce CO₂, thereby suppressing bubble formation. As a powder desiccant, it offers the following advantages:

- Does not alter the physical and chemical properties of the product itself.

- Excellent dispersibility and perfect compatibility with polyethers, isocyanates, and polyols.

- Fast adsorption and strong adsorption capacity.

- Can adsorb carbon dioxide and hydrogen sulfide gases during the production process.

Xintao Activated Molecular Sieve Powder

Xintao has over 20 years of experience in the zeolite powder molecular sieve field, with a professional R&D team and production processes. As a leading domestic manufacturer of powder molecular sieves, Xintao’s product performance rivals that of internationally renowned brands such as UOP and ARKEMA.

Xintao activated molecular sieve powder is made from synthetic molecular sieve powder with special additives and high-temperature calcination. It exhibits excellent dispersibility and fast adsorption, with a static water adsorption value of 23%-27%. It can reduce moisture, eliminate bubbles, improve material uniformity and strength, and extend curing time and service life. Xintao activated zeolite molecular sieves powder are available in a variety of models, including 3A activated molecular sieve powder, 4A activated molecular sieve powder, 5A activated molecular sieve powder, 13X activated molecular sieve powder, and modified activated molecular sieve powder.

Video Introduction

Xintao activated molecular sieve powder offers a professional and efficient dehydration and defoaming solution for polyurethane adhesives thanks to their rapid adsorption and deep water removal capabilities. If you’re looking for a reliable dehydration and defoaming solution, please contact our professional technical team today! We offer free samples and provide targeted product selection advice and technical support for you.

Contact us

Jiangxi Xintao Technology Co., Ltd.

Address: Shangxian West Road, New Third Board Industrial Park, Pingxiang Economic and Technological Development Zone, Pingxiang City, Jiangxi Province

Website: www.xtadsorbents.com

Email: export@xt988.com