Load carbon molecular sieve into nitrogen generator. If it is not filled properly, it is easy to pulverize and affect the nitrogen production effect. Xintao carbon molecular sieve filling guidance will provide you with a solution.

Table of Contents

ToggleBefore loading carbon molecular sieve

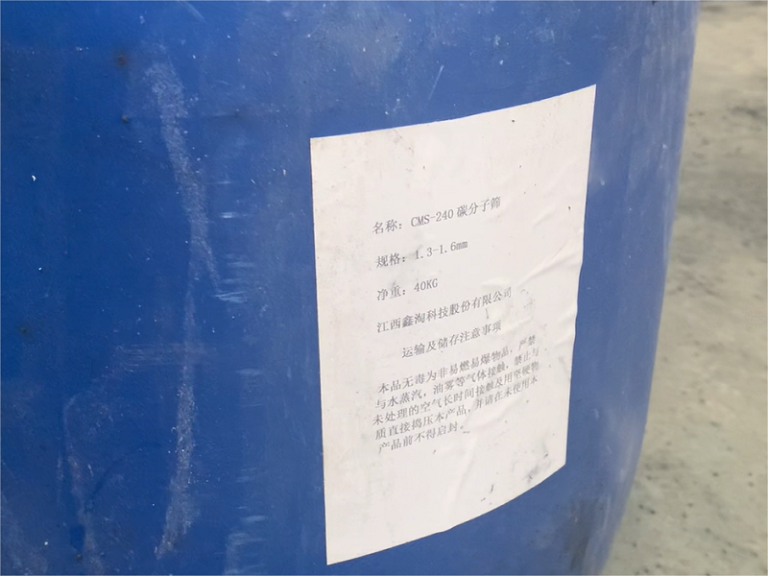

- Prepare the sealed carbon molecular sieve. You need to choose the appropriate carbon molecular sieve according to the nitrogen production requirements of your equipment nameplate. Xintao can provide you with professional advice on this.

- Other filling devices: vibrator; assembly bracket, crane or hoist for the packing tower vertical tube packing assembly; other assembly tools, new sealing gaskets, clean palm pads and cable ties.

- Assemblers: 4 people (recommended);

Operation steps for loading carbon molecular sieve

TIPS: Recommendation A / B tower at the same time, should compare operating conditions for two towers, etc):

1). Normal equipment shutdown (cut off power to the device to stop gas supply) and relief (near atmospheric pressure device, sewerage open);

2). Open the clamping device system (notice the internal parts, you can refer to the manual of the equipment); meanwhile disassembling electrical alarm limit switches and keep records!

3). Use the “driving or hanging gourd” system to carry the carbon molecular sieve adsorbents;

4). Open the flange mouth on the top of Nitrogen adsorption tower, observe carbon molecular sieve cms compensation cavity filler conditions (such as granular plump whether powder, etc.) take out the molecular sieve powder from the adsorption tower first;

5). To the mounting brackets, you can add discretion to compensate for carbon molecular sieve chamber; according to conditions optional vibrating machine;

6). Keep the inner wall of the compensation chamber handle cleaning, fitted with internal compression device system components;

7). Use the “driving or hanging gourd” Mobile clamping device systems, installation accessories (new gasket, clean Palm Mats); with Nitrogen adsorption tower above the right flange assembly;

8). Re-confirm the mechanical, electrical part is installed good!

9). Power on the device (check the power, and the control system is not short circuit fault phenomenon), adjust the limit switch position; determine whether normal (otherwise, in accordance with the electrical maintenance);

10). Closed the sewage system valve, turn the gas supply system, adjust the limit switch one or two stroke position;

11). According to the manual of the equipment, normal operation! And do a good job replacing the carbon molecular sieve process of recording (replacement time, the newly added cms carbon molecular sieve weight, etc.)

12). How to fill cms molecular sieve: select about a 0.75-1KW, frequency of 870 times/minute vibration machine, the device is fixed on the top of the flange. shake vibration 1-5 minutes about 4 times until filling completion.

13). When the nitrogen machine equipment running one hour, checking again clamping device whether fugitive dust declined, if dropped,have to add molecular sieve.

Xintao load carbon molecular sieve for customers