Table of Contents

ToggleSuccessfully Exported Over 10+ Tons of Carbon Molecular Sieve to Europe

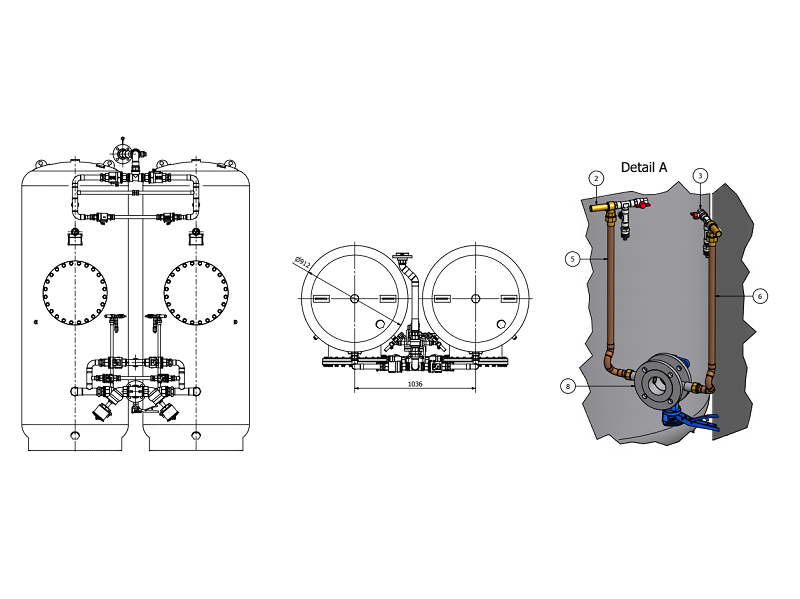

We are proud to announce the successful completion of a significant export project: delivering more than ten tons of high-quality carbon molecular sieves CMS for nitrogen generation to a European client. This achievement underscores our commitment to serving the global market with reliable and efficient adsorption solutions.

The project commenced when we received an inquiry from the customer in late June of last year. Through detailed communication, we understood their application in Pressure Swing Adsorption (PSA) for on-site nitrogen generation. After reviewing their specific parameters, we were confident that our carbon molecular sieve would not only meet but exceed their performance expectations.

While the journey from initial inquiry to final order was lengthy, our team maintained proactive and friendly communication throughout the process. Despite the customer’s project timeline shifting from the end of the year to March and then to June, our persistent engagement paid off. As a dedicated carbon molecular sievemanufacturer, we demonstrated strong production capability by completing the entire manufacturing process for this 10+ ton order—from confirmation to final production—in under two weeks. Our efficient logistics and packaging ensured a compact workflow, allowing us to meet the designated shipping schedule seamlessly.

Carbon Molecular Sieve for Nitrogen Production

Xintao Carbon Molecular Sieves (CMS) are specifically designed for PSA nitrogen generation, capable of producing nitrogen with high purity levels ranging from 99.5% to 99.999%.

Standard Models & Sizes:

Available in models CMS-220, CMS-240, CMS-260, and CMS-280, CMS-300,CMS-330.

Standard particle sizes range from 0.9mm to 2.0mm.

We also accept requests for customized sizes to meet unique application needs.

Composed primarily of carbon, our molecular sieves feature a stable structure and are excellent non-polar materials. They work by selectively adsorbing oxygen from compressed air, thereby enriching and delivering high-purity nitrogen. This PSA process, which operates at normal temperatures and low pressure, offers significant advantages over traditional cryogenic methods—including lower initial investment, faster nitrogen production speed, and reduced operational costs.

As the preferred adsorbent for air separation in PSA systems, the resulting nitrogen is widely used across multiple industries such as:

- Chemical, Oil & Gas

- Electronics & Food Processing

- Pharmaceuticals & Coal Mining

- Cable Industry & Metal Heat Treatment

- Transportation & Storage