Carbon Molecular Sieve Adsorption for Nitrogen Production

Carbon molecular sieve (CMS) is a critical non-polar carbon material widely used in air separation—especially for PSA nitrogen generator. Its unique pore structure and adsorption properties enable efficient oxygen-nitrogen separation under room temperature and low pressure, making it a cost-effective and fast solution for industrial nitrogen production. This article details its definition, working principle and preparation process—including use cases of Xintao Technology’s carbon molecular sieves.

What is Carbon Molecular Sieve Adsorption

Carbon molecular sieve is a non-polar carbon material. As a nitrogen-producing carbon material, it separates air and enriches nitrogen. It adopts room-temperature and low-pressure nitrogen production technology, which brings three key advantages: low investment cost, fast nitrogen production speed, and low nitrogen cost.

The Working Principle of Carbon Molecular Sieve

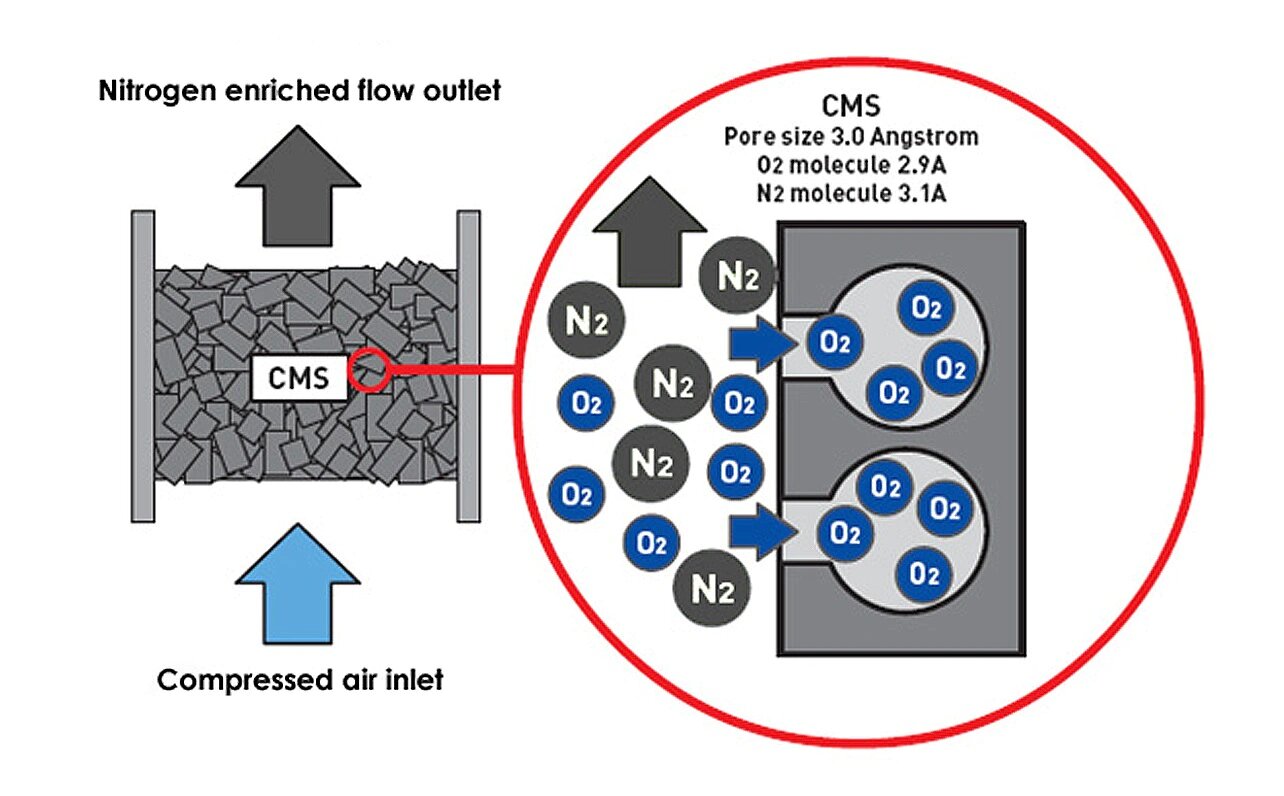

Carbon molecular sieve desiccant uses its sieving characteristics to separate oxygen and nitrogen. When the molecular sieve adsorbs impurity gases, macropores and mesopores only act as channels—they transport adsorbate molecules to micropores and sub-micropores, which serve as the real adsorption spaces.

Nitrogen generation carbon molecular sieve contains a large number of micropores. These micropores allow small dynamic molecules to diffuse quickly into the pores while restricting the entry of large-diameter molecules. Since gas molecules of different sizes have different relative diffusion rates, we can separate the components of the gas mixture.

When producing carbon molecular sieve zeolite, manufacturers design the micropore distribution to be 0.28~0.38nm based on molecular sieving requirements. Within this range, oxygen can diffuse quickly into the pores through micropores, while nitrogen hardly passes through—this achieves oxygen-nitrogen separation.

Micropore diameter is the core basis for carbon molecular sieve to separate oxygen and nitrogen. If the pore diameter is too large, both oxygen and nitrogen molecules can easily enter the micropores, making separation impossible. If the pore diameter is too small, neither oxygen nor nitrogen can enter the micropores, and separation also fails.

Raw Materials and Preparation Process of Carbon Molecular Sieve

Raw Materials:

The raw materials of carbon molecular sieve desiccants are coconut shells, coal, resin, etc., first processing and then powdering, and then blending with the substrate.

Preparation Process:

Pretreatment and Blending: First, the raw materials are processed and powdered, then blended with a matrix. The matrix mainly serves to increase strength and prevent crushing and powdering.

Activation and Pore Formation: In the second step, activation and pore formation are carried out—activators are introduced at an appropriate temperature, which undergo chemical reactions with relatively active non-fixed carbon atoms to expand the surface area and gradually form pores of 10~60nm.

Pore Structure Adjustment: The third step is to adjust the pore structure. Chemical vapors (such as benzene) are used to deposit on the micropore walls of the carbon molecular sieve adsorbent, adjusting the pore size to meet the required specifications.

Contact Xintao

If you have any question, please contact us!