Table of Contents

ToggleApplications of honeycomb ceramics

There are many applications of honeycomb ceramics.

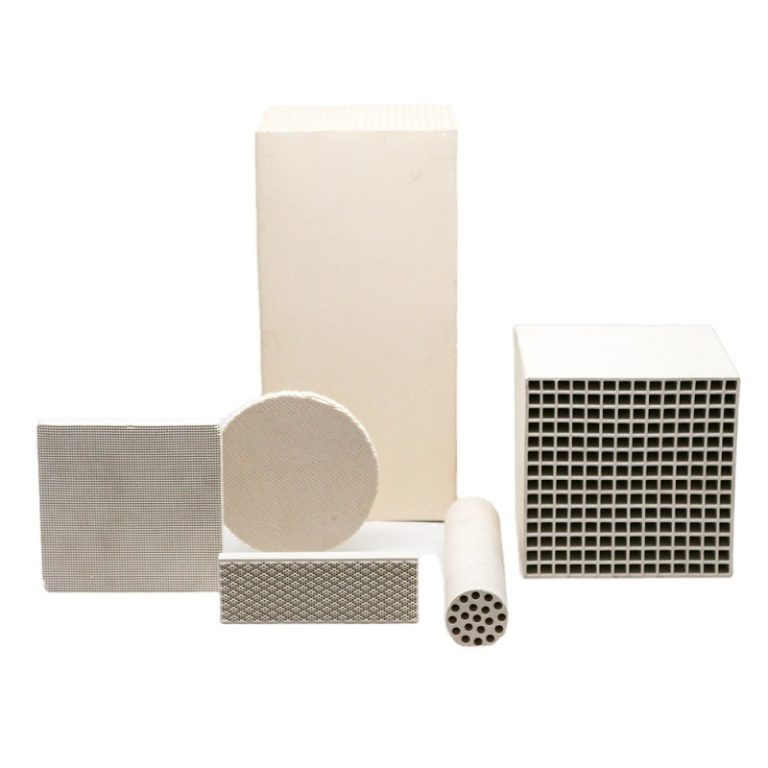

Honeycomb ceramics suited for filter applications, as catalyst carriers or as heat storage media.

Xintao’s Honeycomb ceramic is mainly made of mullite or cordierite with high-quality and high-density straight-hole mesh, which makes it have high thermal shock resistance and high sintering temperature resistance. Its straight hole design ensures the balance between flow and strength, effectively removes industrial waste gas and impurities, etc.

Specifications of Honeycomb Ceramics

Size:100*100*100mm、100*150*150mm、150*150*150mm、150*150*30mm etc.

Hole:25*25、32*32、40*40、43*43、50*50、60*60 etc.

Hole shape:Square、Hexagon、Roundity、Retangle、Triangle etc.

Chemical properties:

SiO2 | Al2O3 | MgO | Fe2O3 | Na2O | K2O |

48-51% | 31-34% | 14-16% | <0.5% | <0.5% | <0.5% |

Introduction of Honeycomb Ceramics

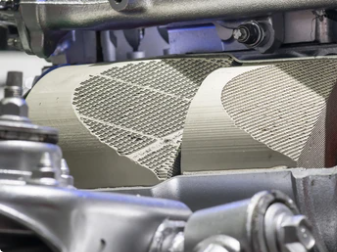

Honeycomb ceramic is widely used in the filtration of hazardous air pollutants, volatile organic compounds in the automotive paint,chemical industry,electronic manufacturing industry,metallurgy and foundry industries.

There are mainly the following applications:

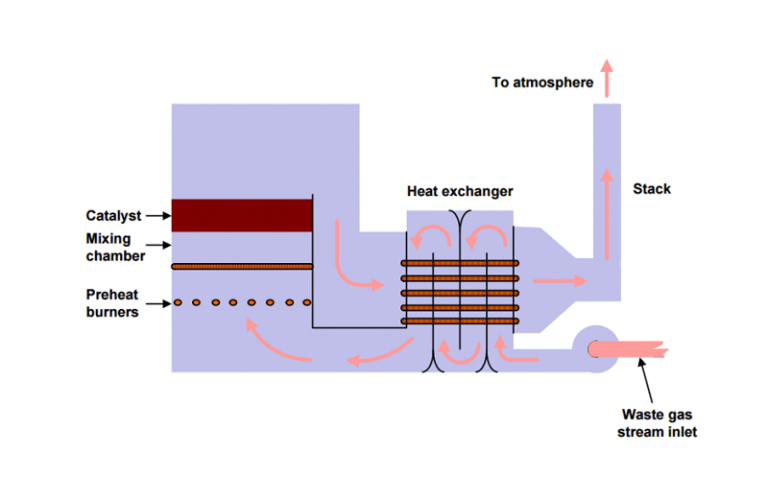

Regenerative Thermal Oxidizer (RTO)

RTO equipment is a type of air pollution control equipment that destroys hazardous air pollutants (HAP), volatile organic compounds (VOC) and odorous emissions created during industrial processes. RTOs are the most common air pollution control technology in use today.

RTO technology uses combustion at high temperatures to oxidize air pollutants from industrial exhaust streams, which turns them into CO2 and H2O before they’re released into the atmosphere. The term “regenerative” in regenerative thermal oxidizer comes from the Ceramic Honeycomb Heat Exchanger, which retains heat from the prior combustion cycle to preheat (and partially oxidize) the pollutant-filled airstream for the next cycle.

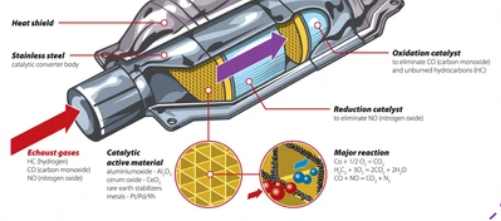

Seletive Catalytic Reduction

SCR technology is one of the most cost-effective and fuel-efficient technologies available to help reduce diesel engine emissions.

SCR can reduce NOx emissions up to 90 percent while simultaneously reducing HC and CO emissions by 50-90 percent, and PM emissions by 30-50 percent. SCR systems can also be combined with a diesel particulate filter to achieve even greater emission reductions for PM.

Xintao Honeycomb Ceramics

For more details, you can visit xintao’s home page:

You can also contact us in the following ways

E-mail: export@xt988.com