Table of Contents

ToggleActivated Alumina European Order for Chloride Removal Solution

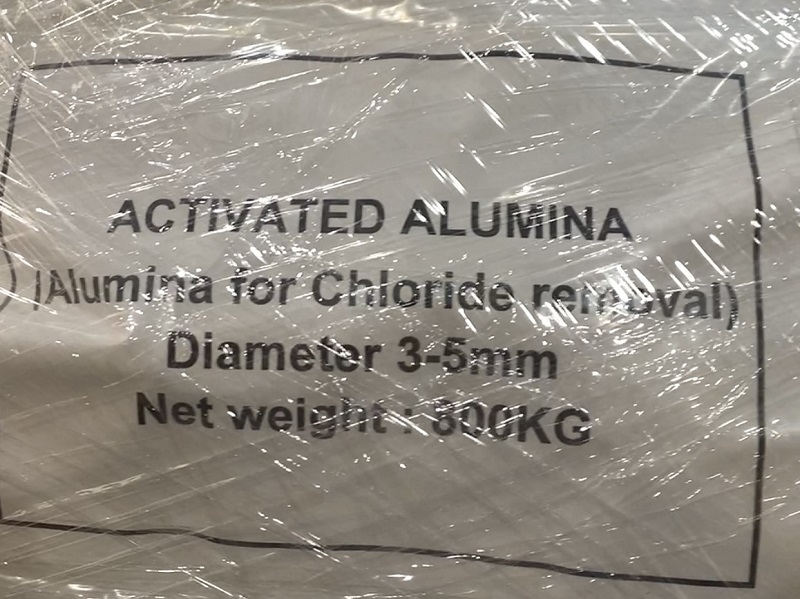

On September 26th, Jiangxi Xintao Technology Co., Ltd. secured an order from a European customer for 6.4 tons of specialized Activated Alumina for chloride removal applications. The customer required this material for processing hydrogen chloride, ethylene glycol, and acetaldehyde streams in their production system.

Upon receiving the inquiry, we promptly provided our technical data sheet and relevant customer references from the same region. After thorough technical discussions, this new client selected Xintao as their qualified supplier, recognizing our product’s capability to meet their specific operational requirements.

Application of Activated Alumina For Chloride Removal

Chloride removal represents a critical step in petrochemical production, where chlorine compounds in feedstock can poison various catalysts and adsorbents, leading to performance degradation and operational failures. The presence of chlorides also causes severe corrosion to equipment and piping systems, ultimately compromising production safety and efficiency.

Xintao’s Activated Alumina for chloride removal delivers performance equivalent to BASF’s CL-750 and CL-760 references. This specialized desiccant offers a wide operating temperature range, consistent low-temperature activity, and excellent water resistance, making it suitable for diverse process conditions.

Xintao’s chloride removal alumina demonstrates versatile application capabilities:

- Effectively protects syngas catalysts and sorbents from chlorine-induced deactivation.

- Widely implemented in naphtha, natural gas, hydrogen, nitrogen, ammonia, and carbon dioxide streams.

- Maintains consistent performance across varying temperature conditions while continuously adsorbing HCl.

The material’s robust adsorption capacity and chemical stability ensure reliable chloride removal, safeguarding downstream equipment and catalysts while extending operational cycles in demanding petrochemical environments.