Jiangxi Xintao Technology Co., Ltd.

There is chemical industry there is Xintao chemical packing.

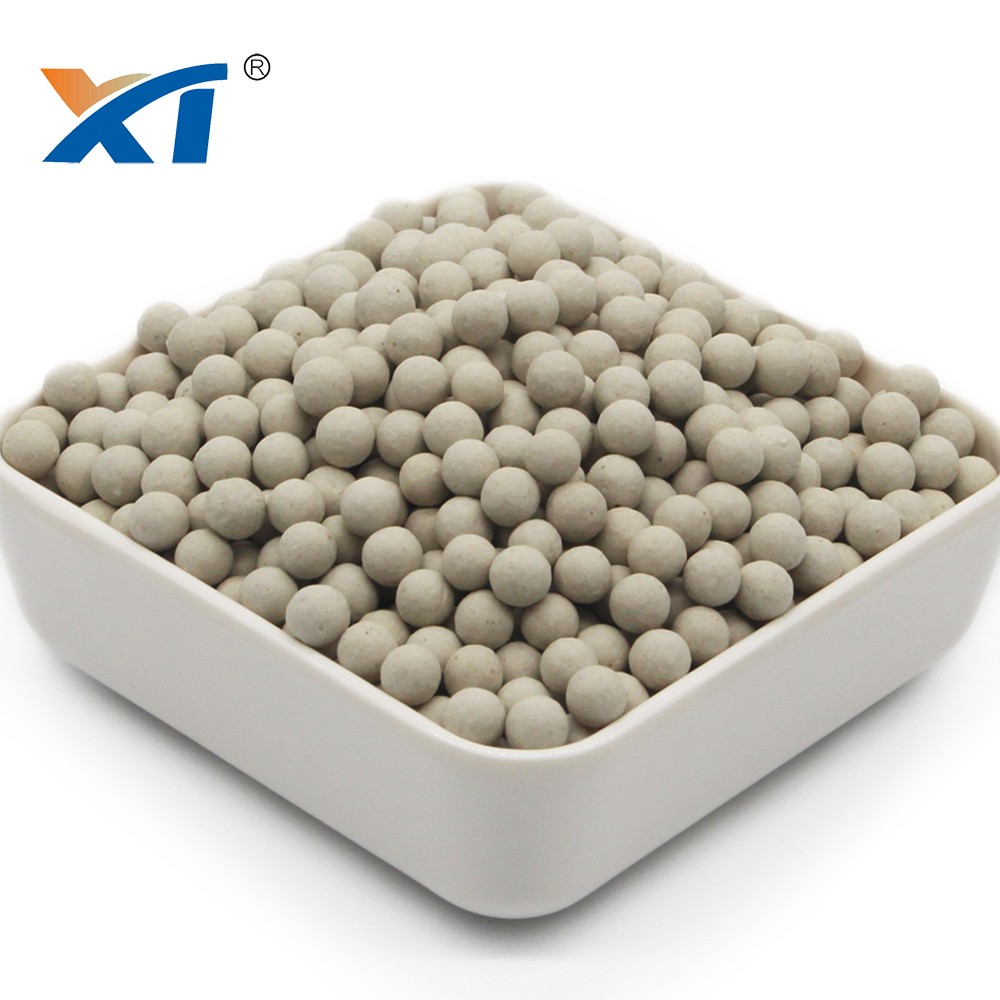

The alumina ceramic ball is based on ultra -fine crystal burn aluminum microfimpen as the raw material. The automatic mixing equipment is evenly mixed by automatic mixing equipment to form a ball machine. The alumina ceramic ball has the characteristics of high temperature resistance, high pressure, low water absorption, stable chemical function, acid resistance, acid resistance, alkali and other solvents, temperature changes during production, and good thermal stability. Its important role is to add an active catalyst that adds gas or liquid distribution points to support and protects low strength.

The indicator data of alumina balls is closely related to alumina content. Generally speaking, the higher the alumina content, the better the performance, the higher the price. This should also be selected according to the needs of users.

What is the difference between alumina ceramic ball and activated alumina ball?

Inert alumina ceramic balls are widely used in oil, chemical, fertilizer, natural gas, environmental protection and other industries, as supporting materials and tower fillers for reactor catalysts. The inert alumina ceramic ball has the characteristics of high temperature resistance, high pressure, low water absorption rate, and stable chemical properties. Can withstand the corrosion of organic solvents such as acid and alkali, and can withstand temperature changes in the production process. Its main function is to increase the active catalysts with low gas or liquid distribution points, support and low protection intensity.

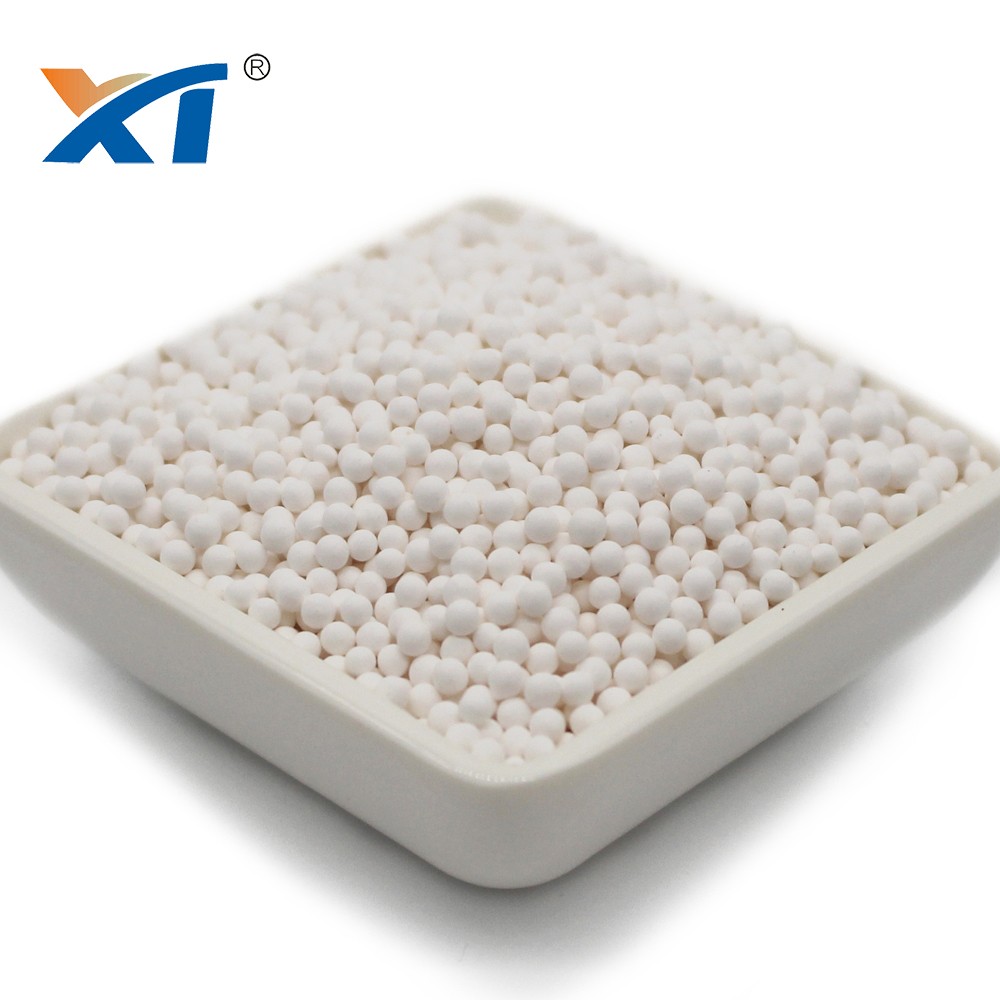

Activated alumina balls, also known as modern water active alum soil. One alumina (Al2O3) is usually called activated alumina. It is a porous, highly decentralized solid material with large surface area. The micro -pore surface has adsorption performance, fluoride performance, dry performance, surface activity, excellent thermal stability Waste the catalyst and catalyst carrier.

Requst For Quotation

Xintao Technology

WhatsApp: +86 13576431529

E-mail: export@xt988.com

Home page:http://www.xtadsorbents.com/

Copyright © Jiangxi Xintao Technology Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a responsefrom us via email. Please be sure to leave yourcontact details so that we can better assist