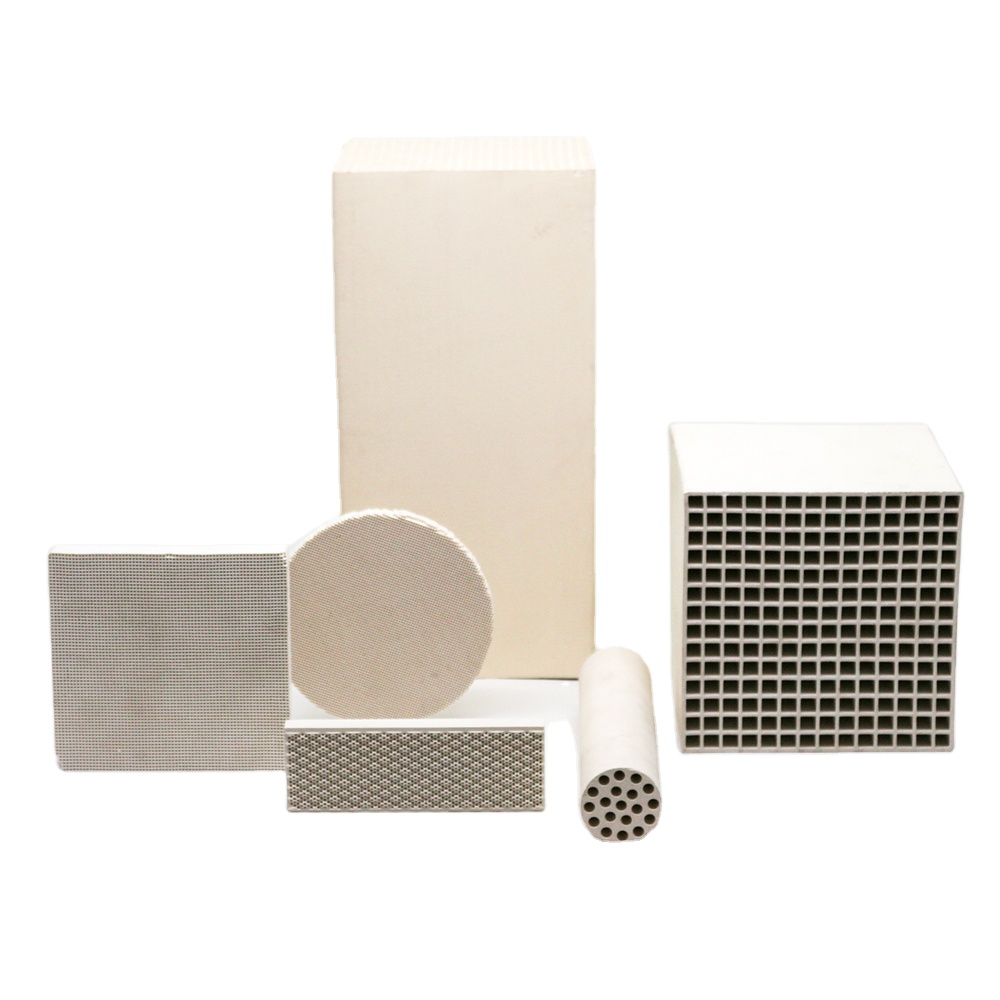

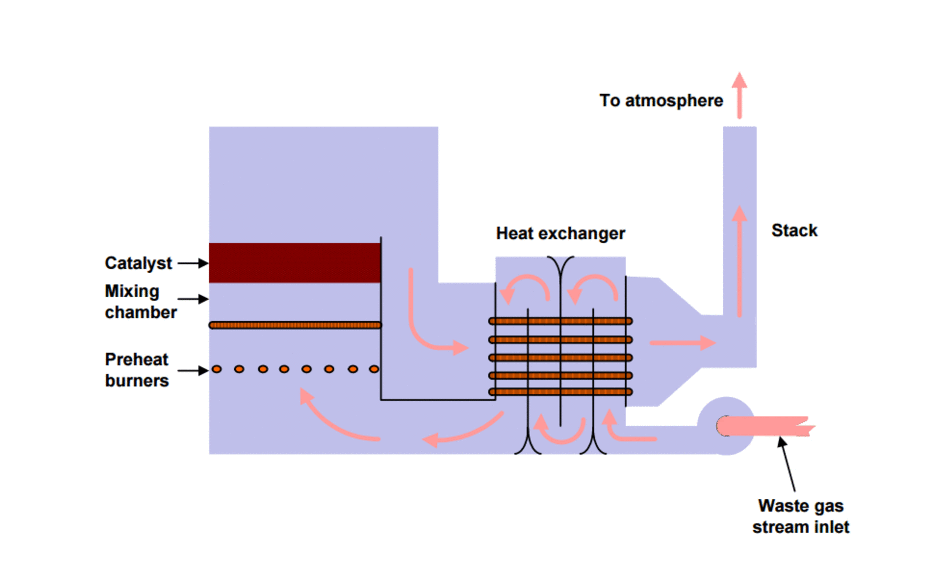

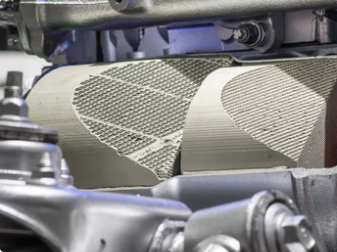

Honeycomb ceramics suited for filter applications, as catalyst carriers or as heat storage media.

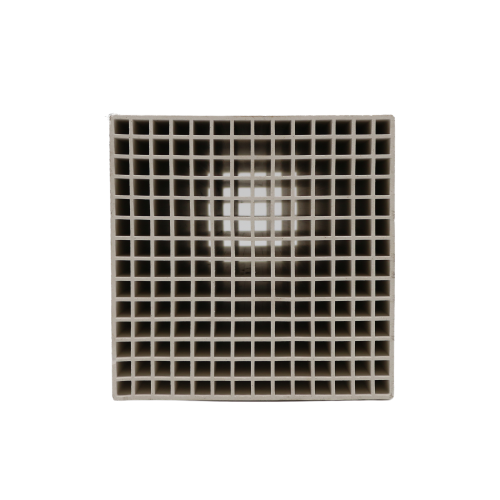

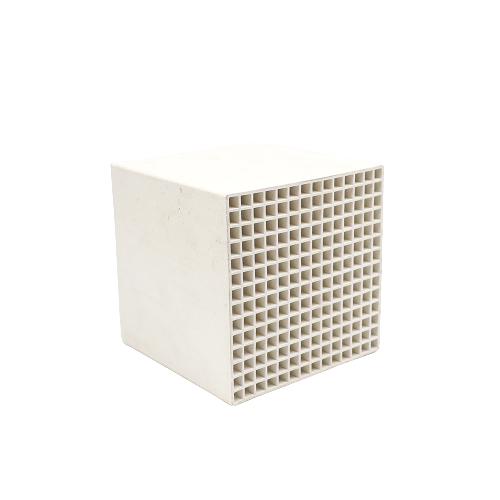

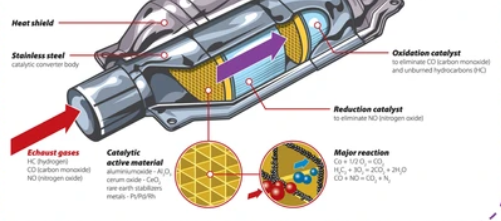

Xintao's Honeycomb ceramic is mainly made of mullite or cordierite with high-quality and high-density straight-hole mesh, which makes it have high thermal shock resistance and high sintering temperature resistance. Its straight hole design ensures the balance between flow and strength, effectively removes industrial waste gas and impurities, etc.