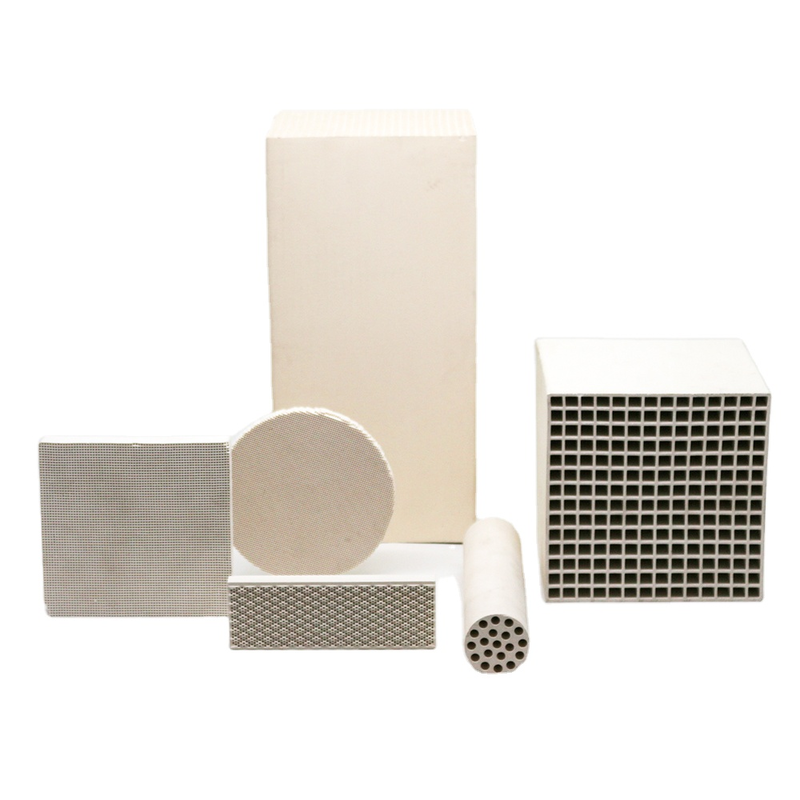

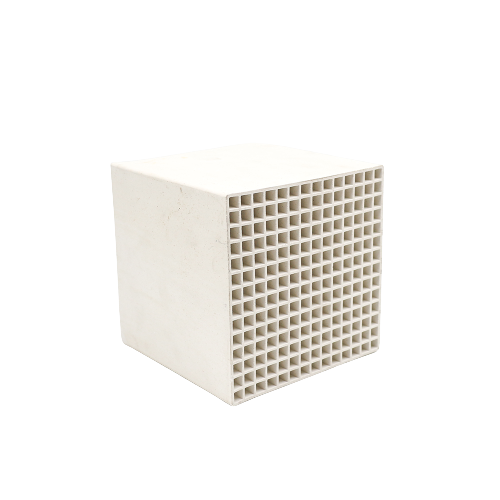

Honeycomb Ceramic

Honeycomb ceramics suited for filter applications, as catalyst carriers or as heat storage media.

Honeycomb ceramic filter is widely used in the filtration of hazardous air pollutants, volatile organic compounds in the automotive paint,chemical industry,electronic manufacturing industry,metallurgy and foundry industries.

Honeycomb ceramic filter is made of mullite ceramic material with high-quality and high-density straight-hole mesh, which makes it have high thermal shock resistance and high sintering temperature resistance. Its straight hole design ensures the balance between flow and strength, effectively removes industrial waste gas and impurities, etc. Seletive Catalytic Reduction

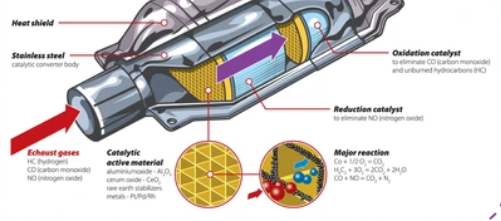

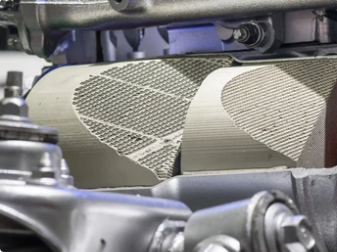

SCR technology is one of the most cost-effective and fuel-efficient technologies available to help reduce diesel engine emissions.

SCR can reduce NOx emissions up to 90 percent while simultaneously reducing HC and CO emissions by 50-90 percent, and PM emissions by 30-50 percent. SCR systems can also be combined with a diesel particulate filter to achieve even greater emission reductions for PM.

Chemical Composition

Technical data

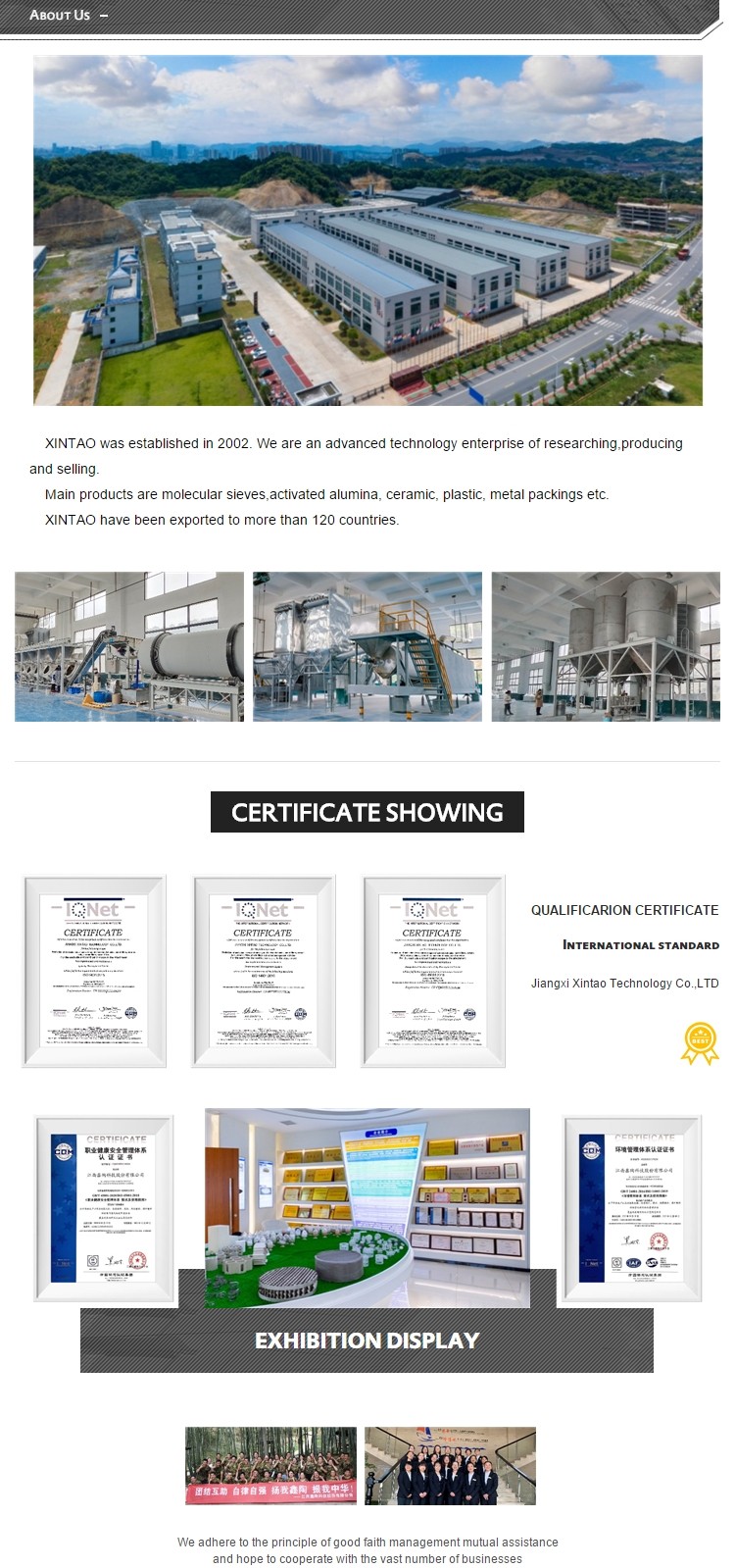

Manufacturing Shop

High-volume mechanized production workshop, providing the highest quality honeycomb ceramic products

Stacking

Corrugated paper interval protection

Packaging

Paper box Wooden box trlet packaging

Transportation

Fast delivery and transportation quality assurance

Known for manufacturing, supplying, wholesaling and exporting a wide range of optimum quality chemical packings, based in jiangxi/pingxiang/anyuan/, was established in the year 2002. Offered chemical range is inclusive of Tower Packing. Available with us at cost-effective prices, these chemicals are extremely appreciated for their compositional accuracy and high effectiveness. In addition to this, our company is engaged in manufacturing, wholesaling and exporting best quality FRP Products - Raw Materials, De-ionized Water, Industrial Solvents Essential Oils Industrial Dyes and Industrial Pigments. Our offered products are extensively used in various industrial applications and are highly demanded by the customers. With the aid of our team of highly dedicated professionals, we have been able to meet the bulk order requirements of production within the stipulated time frame. Our professionals, who hold expertise in their area of operations, are trained on a regular basis through seminars and workshops in order to enhance and polish their technical as well as professionals skills. Highly motivated to attain maximum customer satisfaction, our company strictly follows customer centric approach and transparent business policies, since its inception. We export our products all over the world. We supply to various Tower Packing.